Paint Dust collection

Spray-Tech

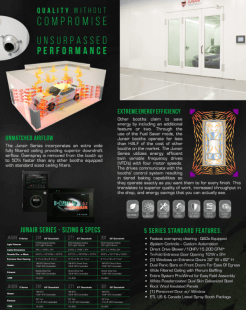

Spray-Tech/Junair dust collection system units are designed to increase the quality of the air. They can also be used to reclaim the coating material used in industrial and commercial finishing processes. Our cylindrical cartridges trap overspray from the powder delivery system, and through the operation of a reverse pulse of air, the excess powder is discharged into a collection tray for reuse. The dust collection system can be further enhanced by incorporating our patented industrial air movement and climate control systems.

DUST COLLECTION FEATURES

White Steel Cabinetes

The cabinet of the dust collection system is made of 12-gauge steel and has a white powder-coated finish.

Plumbing & Valves

Our dust collection systems are equipped with reverse pulse plumbing and valves as a standard feature.

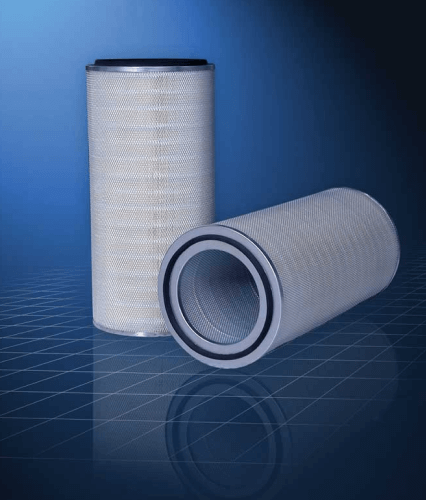

Cartridge Filters

The system contains six cartridge filters that are highly efficient, with a 99% efficiency rating at particles as small as 0.5 microns.

Dust Storage

The dust collection system has three cubic foot capacity drawers for storing collected dust and debris. These drawers are likely used for easy disposal or removal of accumulated dust.

Steel Air Pressure REservoirs

The system includes a steel air pressure reservoir with a thickness of 1/4 inch.

Aluminum POwer

The system is powered by a 5 horsepower backward-inclined aluminum blower, which likely provides the necessary suction for dust collection.

CONTROL PANEL DETAILS

Smart Shut Down Feature

Many dust collection systems can emit dust on shut-down because static pressure is often cut abruptly, our smart shut-down feature gradually reduces static pressure after shut-down and maintains proper static pressure so the system is ready to begin operating immediately the next time it is turned on.

Safety Features

Dust collection system control panels come standard with all required safety features and include a Magnehelic gauge to let you know when to replace the filters on your system.

Smart Pulsing Technology

Our smart pulsing technology helps to reserve energy by pulsing only when necessary. Thanks to this feature our dust collection systems can maintain the proper amount of static pressure, easier. This drastically cuts down on noise around the shop and also greatly extends filter life.

Upgrade Options

The control panel on your dust collection system can be upgraded to our 6th generation touch-screen control panel, in which you will receive customized software that allows you to control every aspect of your booth including multiple variable frequency drives (VFDs). You can also control each of your finishing processes and modify your dust collection system to the type of dust you are collecting.

DUST COLLECTION CONSIDERATIONS

Manufacturing Considerations

- Does the manufacturer meet your shop’s needs?

- Do the parts they manufacture follow proper safety guidelines and OSHA regulations?

- Will the design of the dust collection system fit into my shop?

- Will there be any support after buying the dust collection system?

- Will replacement parts be available if something breaks?

Purchasing Considerations

- Type of work environment

- How powerful a system is needed?

- How loud will the new system be?

- Is the installation process smooth?

RISK CONSIDERATIONS

If you don’t have a dust collecting system, you could be putting your employees’ health at risk by exposing them to hazardous materials such as toxic fumes and particles. Air quality is an essential aspect of any shop; which, makes having a high-quality dust collection system critical. Many fields beyond the automotive arena utilize dust collecting systems, including woodworking, building, manufacturing, and industrial areas.

Fire Hazards

Health Hazards

How is the Dust Explosion Pentagon formed?

SPRAY-TECH PRIORITIZES SAFETY

OSHA - Occupational Safety and Health Administration

Our commitment to safety aligns with OSHA’s guidelines and regulations, ensuring a secure working environment for all.

NFPA - National Fire Protection Association

Spray-Tech is committed to upholding and advancing the rigorous safety measures advocated by NFPA to ensure a secure and compliant environment for our clients.

ETL - Electrical Testing Labs

We work hard to meet ETL standards in order to ensure our electrical equipment meets rigorous safety and performance criteria.

EPA - Environmental Protection Agency

Our environmental responsibility is reflected in our compliance with EPA regulations, contributing to a cleaner and sustainable future.