Automate complicated industrial processes with our smart and advanced Industrial Finishing Solutions

We offer the most efficient and advanced Industrial Finishing Solutions in the United States.

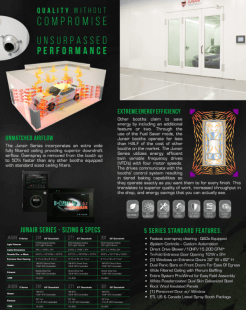

A leading name in the field of manufacturing high performance automotive and industrial finishing solutions, Spray-Tech/Junair helps companies automate much of their finishing processes. From spraying, coating, curing, dust collection, and more, our automated finishing systems can handle any finishing task with utmost efficiency while saving precious time, energy, and resources. If you want your business operations to be more productive and provide a safe environment for your workers, contact us. We will offer you the most suitable solutions catering to your specific needs.

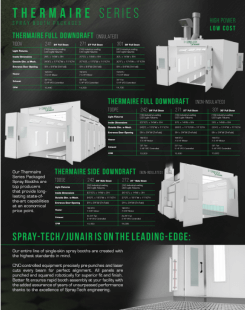

For more than two decades, Spray-Tech/Junair has become a leading manufacturer of various finishing equipment for different industries. From automotive, aerospace, powder coating/curing to industrial finishing solutions, we design and manufacture world-class equipment that complies with OSHA and NFPA. Our finishing systems and paint spray booths are equipped with highly innovative features for easy operations and extremely satisfying results. You can rest assured that your team will work more effectively and efficiently with our equipment than ever before. Register and access our downloadable brochures, exclusive content, company updates, and a notice of ongoing deals.

Industrial Finishing Systems

Spray-TEch

Spray-Tech/Junair understands exactly what it takes to get the right finish. We have built systems for powder coating, paint application, and everything in between.

Industrial Finishing

Solutions

Made In The USA

Custom Finishing

SprayTech is proud to manufacture all of our finishing equipment in the United States.

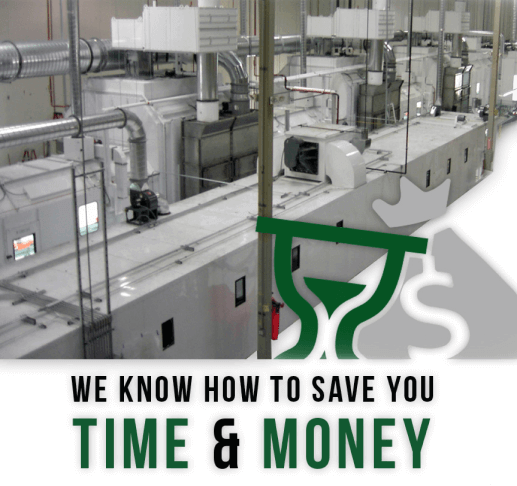

Spray-Tech/Junair is proud to manufacture all of our finishing equipment in the United States. It allows us to provide higher-quality products while remaining competitive. As a leading company in this highly competitive industry, Spray-Tech/Junair has manufactured completely automated industrial finishing solutions that can accomplish any finishing task you have with utmost efficiency while cutting down on unnecessary costs and saving precious time. We have over two decades of experience, which allows us to have all the right tools and technical know-how to build and engineer all sorts of equipment, including environmental rooms, dust collectors, and water wash exhausts.

We also build our own air make-up systems and industrial light fixtures, in-house, under the brand Mercury. Mercury produces some of the best air make-up systems in the world. Nobody beats Mercury’s industrial LED light fixtures, made specifically for use in industrial finishing solutions.

Why Should You Choose

Spray-Tech?

Spray-Tech/Junair likes to raise the bar when it comes to finishing technology. Our engineers carry years of expertise working on various finishing processes and use their knowledge to design finishing systems that perform efficiently and operate with ease.

Everything from our control panels and advanced components, to our heaters and light fixtures, is produced in-house and designed from the ground up. Over the years, Spray-Tech/Junair has developed industrial finishing solutions that withstand the test of time. Thanks to the fine attention to detail our team takes, we are familiar with every finishing process and component down the line.

Have any queries or suggestions? Drop us a line, and we will get back to you at the earliest.

Start To Finish

Quality Products

Spray-Tech/Junair likes to raise the bar when it comes to finishing technology. Our engineers carry years of expertise working on various finishing processes and use their knowledge to design finishing systems that perform efficiently and operate with ease.

Everything from our control panels and advanced components, to our heaters and light fixtures, is produced in-house and designed from the ground up. Over the years, Spray-Tech/Junair has developed industrial finishing solutions that withstand the test of time. Thanks to the fine attention to detail our team takes, we are familiar with every finishing process and component down the line.

Have any queries or suggestions? Drop us a line, and we will get back to you at the earliest.

Spray-Tech/Junair likes to raise the bar when it comes to finishing technology. Our engineers carry years of expertise working on various finishing processes and use their knowledge to design finishing systems that perform efficiently and operate with ease.

Everything from our control panels and advanced components, to our heaters and light fixtures, is produced in-house and designed from the ground up. Over the years, Spray-Tech/Junair has developed industrial finishing solutions that withstand the test of time. Thanks to the fine attention to detail our team takes, we are familiar with every finishing process and component down the line.

Have any queries or suggestions? Drop us a line, and we will get back to you at the earliest.

Why Should You Choose

Spray-Tech?

Our Products Are Built to Last

Spray-Tech/Junair employs fiber optic laser technology and precision CNC controlled fabrication equipment to ensure perfect alignment. All panels are squared robotically for superior fit and finish, allowing fast installations and years of unparalleled performance.

No matter what the application calls for — dust collecting, paint finishing, powder curing, or completely clean enclosures — we take pride in our systems’ ability to achieve maximum throughput and efficiency while remaining user-friendly and easily operable.

We Provide Custom Industrial Finishing Solutions

We have been an innovator in the finishing industry for over 25 years. We proudly call ourselves experts at designing and building highly customized solutions, including exotic draft configurators and even outfitting the entire factories with an entirely automated finishing process. Whatever it is, we can help. Call us today for world-class Industrial finishing solutions and finishing technology.

We Are Pioneers in Industrial Finishing

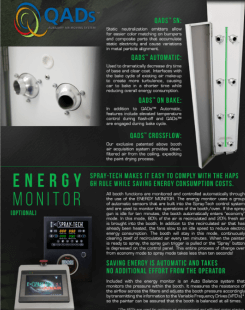

At Spray-Tech/Junair, we exercise lean manufacturing principles to ensure our systems use less energy and do their job more efficiently than the vast majority of systems you see on the market today.

This is something we believe in wholeheartedly. It is why our manufacturing facility has been able to offset the cost of our energy consumption by 99% by installing highly-efficient solar panels on our roof.

Get a quick estimate of your industrial finishing needs.

We Have the Types of Industrial Finishing

Solutions You Need

Industrial finishing is performed on a metallic, plastic, or any wood surface to improve the surface’s appearance, adhesion, or wettability. Most commonly, industrial finishing is performed in the automotive industry, OEM based products, or in the telecommunication industries. Plating, brushing, polishing, grinding, blessing, heat treatments, coating, hot blackening, and vibration are some popular types of industrial finishings.

Products Built to Last

Spray-Tech/Junair employs fiber optic laser technology and precision CNC controlled fabrication equipment to ensure perfect alignment. All panels are squared robotically for superior fit and finish, allowing fast installations and years of unparalleled performance.

No matter what the application calls for — dust collecting, paint finishing, powder curing, or completely clean enclosures — we take pride in our systems’ ability to achieve maximum throughput and efficiency while remaining user-friendly and easily operable.

Pioneers in Industrial Finishing

At Spray-Tech/Junair, we exercise lean manufacturing principles to ensure our systems use less energy and do their job more efficiently than the vast majority of systems you see on the market today.

This is something we believe in wholeheartedly. It is why our manufacturing facility has been able to offset the cost of our energy consumption by 99% by installing highly-efficient solar panels on our roof.

Get a quick estimate of your industrial finishing needs.