Industrial Finishing Batch Ovens

PAINT FINISHING BATCH OVENS

Spray-Tech ovens are a reliable and efficient way to dry, cure, bake, or preheat products in your batch systems line. Our walk-in ovens are customizable, OSHA & NFPA compliant, and equipped state of the art equipment. Ovens are custom designed for specific applications. Spray-Tech ovens are equipped with air heat burners and standard PID controllers for precise temperature control. Our supply and return ductwork, as well as adjustable nozzles, ensure excellent heat temperature uniformity and heating rates.

FEATURES

Oven Panels

Oven panels are constructed with two 20 gauge steel panels and a proprietary heat isolation structure to ensure panel rigidity and low heat loss. The exterior panel is made of G-90 galvanized steel for corrosion resistance while the interior steel panel is aluminized helping ensure excellent heat distribution and uniformity. Panels are insulated with 850° rock wool*.

Batch Timers

Spray-Tech/Junair includes built-in batch timers and loud audible alerts with every oven to ensure maximum usability and convenience.

Efficiency

Spray-Tech/Junair produces low-emission, high-quality and energy efficient industrial process ovens which ensure increased productivity and lower overall costs

TECHNOLOGY

LED Control Panels

Standard oven control panels include LED light troubleshooting indicators for reliable operational management and ease of use. Our Smart Control system utilizes the latest technology to ensure optimum output & information at a glance.

Low Friction Hinges

All ovens come with adjustable low-friction hinges that need little maintenance thanks to the included high-wear bronze bushings

Temperature Control

Spray-Tech/Junair’s Class A ovens feature a +/- 10° temperature saturation throughout the entire enclosure with a 500°F maximum temperature. This even distribution of temperature provides optimal curing results.

FEATURES

Oven Panels

Oven panels are constructed with two 20 gauge steel panels and a proprietary heat isolation structure to ensure panel rigidity and low heat loss. The exterior panel is made of G-90 galvanized steel for corrosion resistance while the interior steel panel is aluminized helping ensure excellent heat distribution and uniformity. Panels are insulated with 850° rock wool*.

Batch Timers

Spray-Tech/Junair includes built-in batch timers and loud audible alerts with every oven to ensure maximum usability and convenience.

Efficiency

Spray-Tech/Junair produces low-emission, high-quality and energy efficient industrial process ovens which ensure increased productivity and lower overall costs

TECHNOLOGY

LED Control Panels

Standard oven control panels include LED light troubleshooting indicators for reliable operational management and ease of use. Our Smart Control system utilizes the latest technology to ensure optimum output & information at a glance.

Low Friction Hinges

All ovens come with adjustable low-friction hinges that need little maintenance thanks to the included high-wear bronze bushings

Temperature Control

Spray-Tech/Junair’s Class A ovens feature a +/- 10° temperature saturation throughout the entire enclosure with a 500°F maximum temperature. This even distribution of temperature provides optimal curing results.

BATCH OVEN DETAILS

Energy Savings

Our ovens come with six-inch panels that reduce heat loss and save energy

Reliable Structure

Heavy internal structural steel frame supports oven body and heater cabin

Air Plenums

Spray-Tech/Junair includes air plenums that run the full-length of the oven to ensure maximum uniformity of temperature throughout.

Customizable Sizes

Popular sizes include: 8x12x8, 10x12x8, and 14x12x8. We will customize the oven to your floor needs.

Professional Duct Work

All of our duct work is laser cut and precision formed

Industrial Burners

Industrial proportioning burners with best-in-class train components

Energy Savings

Our ovens come with six-inch panels that reduce heat loss and save energy

Reliable Structure

Heavy internal structural steel frame supports oven body and heater cabin

Air Plenums

Spray-Tech/Junair includes air plenums that run the full-length of the oven to ensure maximum uniformity of temperature throughout.

Customizable Sizes

Popular sizes include: 8x12x8, 10x12x8, and 14x12x8. We will customize the oven to your floor needs.

Professional Duct Work

All of our duct work is laser cut and precision formed

Industrial Burners

Industrial proportioning burners with best-in-class train components

Get pricing or connect with the support team.

get pricing or connect with the support team.

If you are looking for a Quick Estimate on any of our products, please fill out the short form below so our sales team can help you with pricing.

ADDITIONAL FINISHING PRODUCTS

Environmental Rooms

We oversee every step of the manufacturing process from design through installation.

High Efficiency Convection Ovens

Spray Tech engineers and builds drying and curing ovens to provide excellent temperature uniformity around the part profile throughout the heating process for both liquid and powder curing applications.

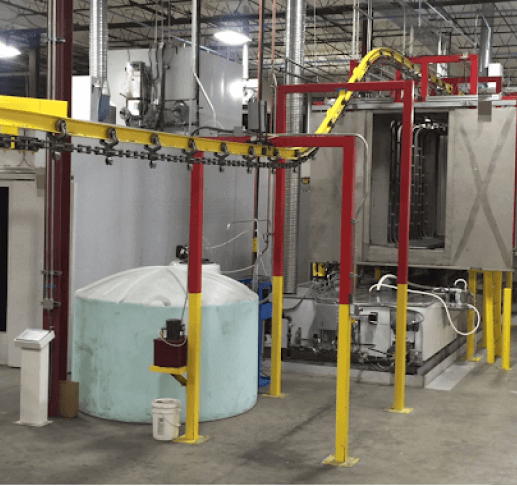

Pre-Treatment Washer

The integrity of the paint finishing process begins with pre-treatment. It is the first step in the finishing line, and it’s critical to the outcome of the final paint quality.