Gas & Electric Paint Finishing Ovens

Gas & Electric Finishing Ovens

At Spray-Tech, we specialize in crafting a wide range of custom power coating ovens, including conveyor belt systems and batch ovens. Our expertise extends to providing top-tier paint curing solutions for all industries, ensuring that no matter the project, Spray-Tech delivers efficiency, precision, and reliability. Our commitment to quality makes us a reliable option for your oven and systems needs.

At Spray-Tech, we specialize in crafting a wide range of custom power coating ovens, including conveyor belt systems and batch ovens. Our expertise extends to providing top-tier paint curing solutions for all industries, ensuring that no matter the project, Spray-Tech delivers efficiency, precision, and reliability. Our commitment to quality makes us a reliable option for your oven and systems needs.

Conveyor ovens

Conveyor Ovens

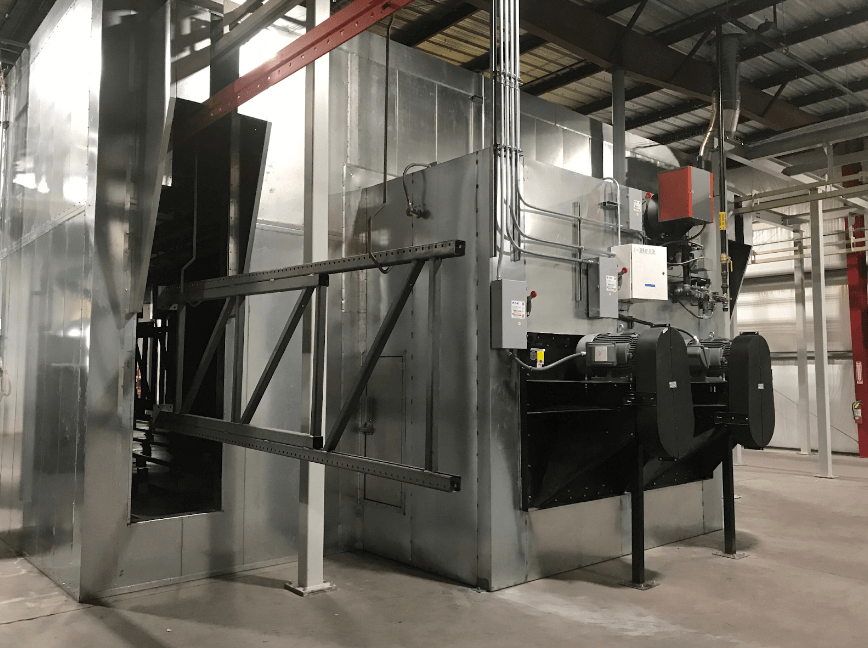

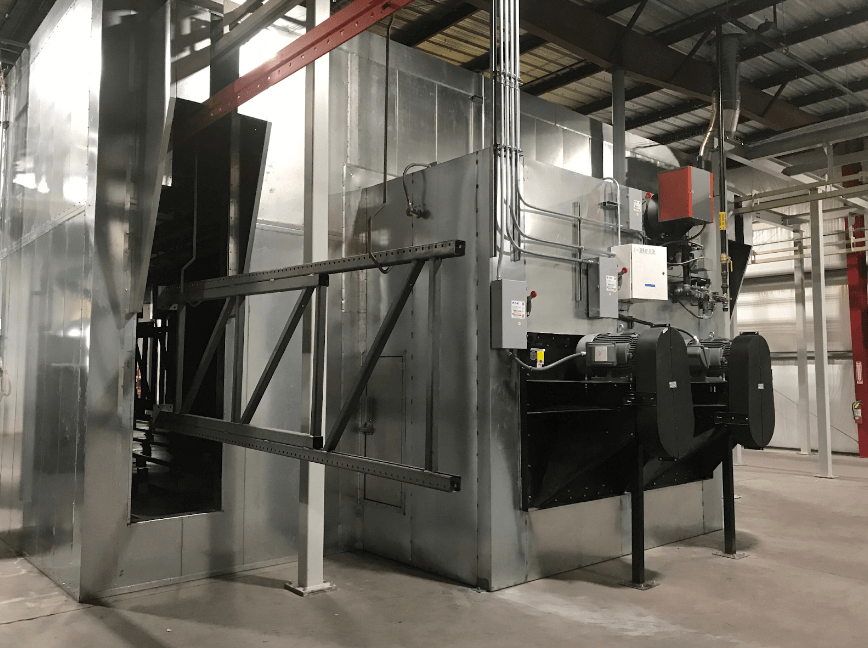

Our conveyor ovens deliver unmatched efficiency and superior finish quality for a broad spectrum of industrial applications. Engineered with robust construction, these ovens are the ideal solution for businesses aiming to optimize their painting and finishing processes. The advanced design ensures consistent temperature control and uniform heat distribution, resulting in flawless finishes every time.

Our products are built to last, providing reliable performance even in the most demanding environments. They are equipped with state-of-the-art features, including automated controls for precise operation and energy-efficient systems to reduce operational costs. Whether you are in the automotive, aerospace, or metalworking industry, our conveyor ovens are designed to meet your specific needs, enhancing productivity and ensuring top-tier quality for your products.

Investing in our conveyor ovens means investing in quality, efficiency, and reliability. Enhance your production line with our cutting-edge technology and experience the difference in your finishing processes.

Our conveyor ovens deliver unmatched efficiency and superior finish quality for a broad spectrum of industrial applications. Engineered with robust construction, these ovens are the ideal solution for businesses aiming to optimize their painting and finishing processes. The advanced design ensures consistent temperature control and uniform heat distribution, resulting in flawless finishes every time.

Our products are built to last, providing reliable performance even in the most demanding environments. They are equipped with state-of-the-art features, including automated controls for precise operation and energy-efficient systems to reduce operational costs. Whether you are in the automotive, aerospace, or metalworking industry, our conveyor ovens are designed to meet your specific needs, enhancing productivity and ensuring top-tier quality for your products.

Investing in our conveyor ovens means investing in quality, efficiency, and reliability. Enhance your production line with our cutting-edge technology and experience the difference in your finishing processes.

Batch Ovens

Batch Ovens

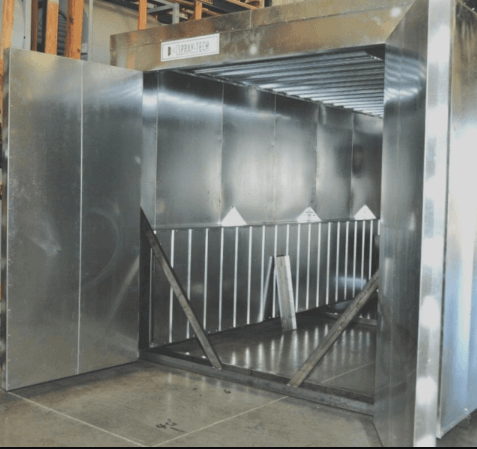

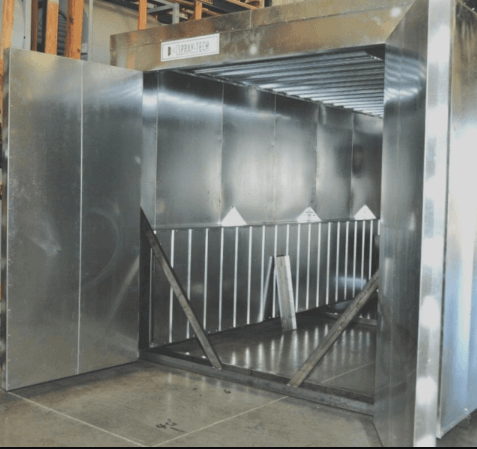

Spray Tech builds custom batch ovens with the same industry expertise as our continuous ovens. Each oven is designed specifically for its intended application, taking into account part size and production volumes to determine the optimal configuration. Equipped with air heat burners and standard PID controllers, our ovens ensure precise temperature control. The supply and return ductwork, along with adjustable nozzles, guarantee excellent heat uniformity and efficient heating rates. Constructed for low maintenance and long service life, Spray Tech ovens come in a variety of sizes to meet specific customer requirements.

Our ovens feature six-inch panels to reduce heat loss and save energy, supported by a heavy internal structural steel frame for the oven body and heater cabinet. They come with options for manual swing doors or automatic door operators. The ductwork is laser-cut and precision-formed, with louvered supply and return ducts for precise temperature control. Industrial proportioning burners and best-in-class gas train components, along with PID proportioning controllers, optimize temperature control and prevent overshoot. These ovens maintain tight temperature uniformity to meet both powder and liquid coating specifications and offer recirculating air filtration options.

Spray Tech builds custom batch ovens with the same industry expertise as our continuous ovens. Each oven is designed specifically for its intended application, taking into account part size and production volumes to determine the optimal configuration. Equipped with air heat burners and standard PID controllers, our ovens ensure precise temperature control. The supply and return ductwork, along with adjustable nozzles, guarantee excellent heat uniformity and efficient heating rates. Constructed for low maintenance and long service life, Spray Tech ovens come in a variety of sizes to meet specific customer requirements.

Our ovens feature six-inch panels to reduce heat loss and save energy, supported by a heavy internal structural steel frame for the oven body and heater cabinet. They come with options for manual swing doors or automatic door operators. The ductwork is laser-cut and precision-formed, with louvered supply and return ducts for precise temperature control. Industrial proportioning burners and best-in-class gas train components, along with PID proportioning controllers, optimize temperature control and prevent overshoot. These ovens maintain tight temperature uniformity to meet both powder and liquid coating specifications and offer recirculating air filtration options.

Product Details

Additional Components

Spray-Tech/Junair ovens are designed with air plenums that run the full length of the paint curing oven, ensuring maximum uniformity of temperature throughout. Each oven includes built-in batch timers and loud audible alerts to enhance usability and convenience. Standard industrial oven control panels feature LED light troubleshooting indicators for reliable operational management and ease of use. Our Smart Control system utilizes the latest technology to provide optimum output and accessible information at a glance. We use only top-of-the-line brand name components in our ovens, ensuring a long-lasting, quality product. Additionally, all paint curing ovens come with adjustable low-friction hinges that require minimal maintenance, thanks to the included high-wear bronze bushings.

Spray-Tech/Junair ovens are designed with air plenums that run the full length of the paint curing oven, ensuring maximum uniformity of temperature throughout. Each oven includes built-in batch timers and loud audible alerts to enhance usability and convenience. Standard industrial oven control panels feature LED light troubleshooting indicators for reliable operational management and ease of use. Our Smart Control system utilizes the latest technology to provide optimum output and accessible information at a glance. We use only top-of-the-line brand name components in our ovens, ensuring a long-lasting, quality product. Additionally, all paint curing ovens come with adjustable low-friction hinges that require minimal maintenance, thanks to the included high-wear bronze bushings.

Advanced Control Panels

Included on our standard control panel is a diagnostic light bar making it simple for you to troubleshoot any issues at a glance, without the need of calling a service technician.

Spray-Tech/Junair an optional control panel with touch-screen functionality, eight (8) programmable ramp/soak operations for stepped composite curing, and detailed on-board troubleshooting information.

Standard control panel with P.I.D. high temperature limit, hour meter and digital batch timer with alarm. Screenshots of optional touch-screen control panel shown.

Request an Estimate

Included on our standard control panel is a diagnostic light bar making it simple for you to troubleshoot any issues at a glance, without the need of calling a service technician.

Spray-Tech/Junair an optional control panel with touch-screen functionality, eight (8) programmable ramp/soak operations for stepped composite curing, and detailed on-board troubleshooting information.

Standard control panel with P.I.D. high temperature limit, hour meter and digital batch timer with alarm. Screenshots of optional touch-screen control panel shown.

Request an Estimate

Energy Efficient Finishing Ovens

When it comes to finishing equipment, Spray Tech / Junair provides the most energy efficient and effective solutions. Our industrial oven panels are built from the ground up using 3D modeling software to ensure the ovens provide the most energy efficient and effective solutions possible. All our equipment is OSHA and NFPA compliant which ensures your manpower gets a safe and productive environment to work in. Equipped with the highest innovative features, these ovens are manufactured by a competent team of engineers and technicians to deliver exceptional performance and results that are over and beyond your expectations.