Premium Automotive Paint Booths

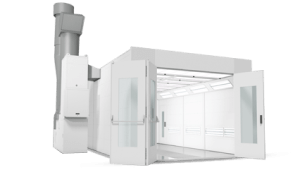

Premium Car Paint Booths

Explore our selection of ready-to-order, fully equipped car paint booths. We also specialize in designing custom spray booths tailored to meet your specific requirements. Contact us today for a quick estimate and learn more about our world-class automotive paint booth products and their unique configurations.

Explore our selection of ready-to-order, fully equipped car paint booths. We also specialize in designing custom spray booths tailored to meet your specific requirements.

Paint Booth Specifications

Paint Booth Specifications

Customize Your Airflow

Reverse flow, side downdraft, full downdraft, and front flow airflow options are available

Select Your Product Line

We offer a variety of paint booth models, including our Junair, Premier, Power, and Thermaire models

Controls

Standard features include user programmable controls, allowing unparalleled process customization utilizing PLC and HMI technologies through a simple to-use touch screen interface.

Construction

Constructed with 18 gauge galvanized steel. Includes double layer 14-gauge stiffeners assembled with carriage bolts.

Doors

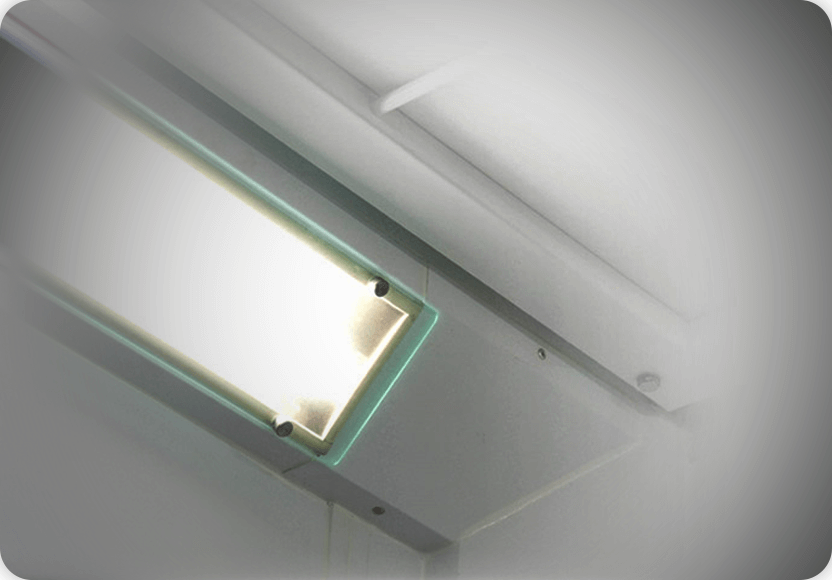

All personnel doors are placed per code, double skinned with UL listed fire door frames and include large tempered glass windows.

Code Compliance

Safety and code compliance is our top priority, guiding the design of every paint booth we offer.

Customize Your Airflow

Reverse flow, side downdraft, full downdraft, and front flow airflow options are available

Select Your Product Line

We offer a variety of paint booth models, including our Junair, Premier, Power, and Thermaire models

Controls

Standard features include user programmable controls, allowing unparalleled process customization utilizing PLC and HMI technologies through a simple to-use touch screen interface.

Construction

Constructed with 18 gauge galvanized steel. Includes double layer 14-gauge stiffeners assembled with carriage bolts.

Doors

All personnel doors are placed per code, double skinned with UL listed fire door frames and include large tempered glass windows.

Code Compliance

Safety and code compliance is our top priority, guiding the design of every paint booth we offer.

Paint Booth Product Lines

Paint Booth Product Lines

Cutting Edge

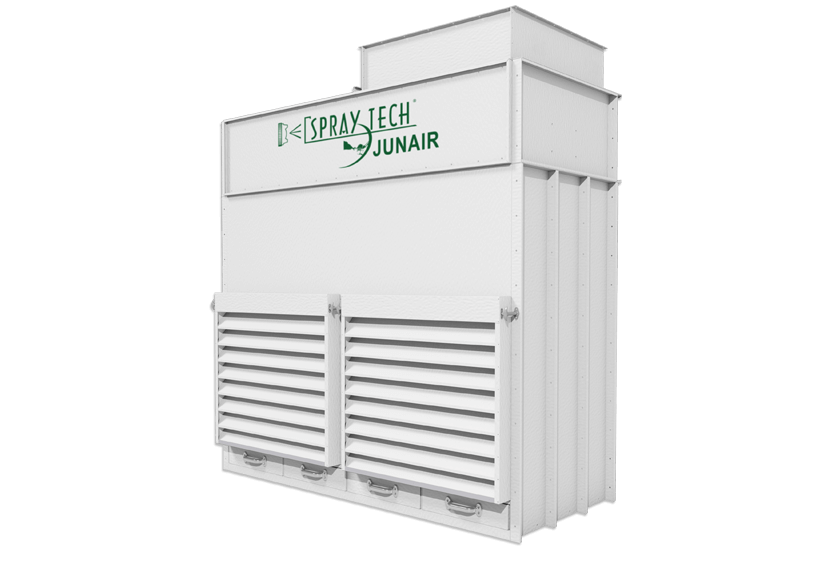

Junair Series

Junair Series booths offer unparalleled operator automation, superior refinishing environments and the lowest energy usage available. Call for more information on this premium option.

High Performance

Premier Series

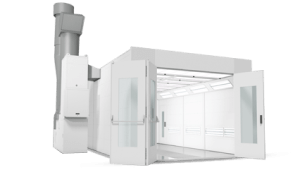

The premier series paint booths provide an excellent finish among any paint booths in the industry. The advanced control panel and high tech features of this series make the life of the auto body shop owner extremely easy.

Small Footprint

Power Series

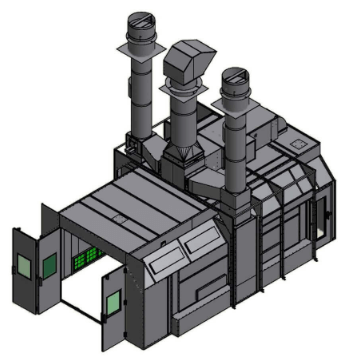

The Power series paint booths utilize highly advanced technology and incorporate air-make-up units above the paint booth to save floor space. Configured to any air flow movement.

Economical Models

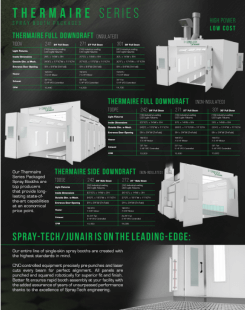

Thermaire Series

Thermaire paint booths are an affordable option. It provides a simple operator interface with all of the air movement, heat, and lighting needed for great paintwork.

Configured to any air flow movement.

Custom Airflow Options

Custom Airflow Options

Semi Down-Draft

Improved Airflow Pattern: Air enters through the ceiling at the front of the booth and moves diagonally towards the rear and downward, enhancing paint quality by minimizing dust and overspray accumulation on the painted surface.

Balance of Cost and Quality: Offers a balance between the cost-effectiveness of cross draft and the superior finish quality of full down-draft systems.

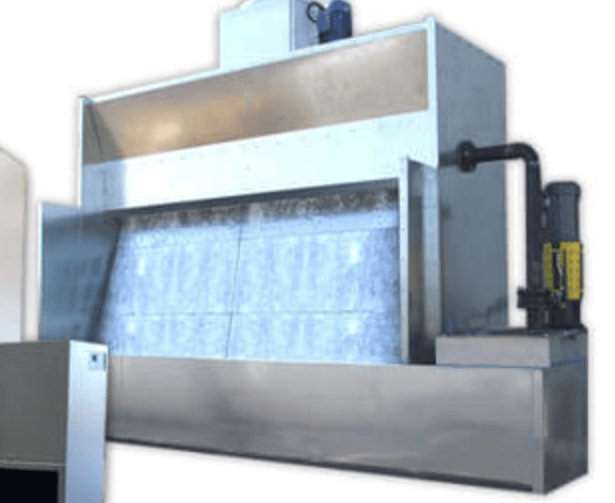

Cross Draft

Cost Efficiency: Cross draft booths are typically less expensive to build and install since they require simpler ductwork and fewer fans.

Even Airflow: Air enters through filters at one end of the booth and moves horizontally across the vehicle towards the exhaust at the opposite end, providing even airflow that helps achieve a consistent finish.

Side-draft

Vertical Airflow: Air enters through filters on the side walls and moves horizontally across the work area before exiting through filters on the opposite side, reducing the chances of contaminants settling on wet surfaces.

Enhanced Visibility: This setup often provides better lighting and visibility as the airflow supports a cleaner and clearer working environment, essential for precision tasks.

Down-draft

Superior Finish Quality: Air enters from the ceiling and moves downward over the object, exiting through the floor. This vertical airflow pattern helps carry contaminants and overspray away from the vehicle, resulting in a cleaner and higher-quality finish.

Reduced Contamination: The downward flow reduces the likelihood of dust or particles settling on the surface during painting, which is crucial for achieving a flawless finish.

Semi Down-Draft

Improved Airflow Pattern: Air enters through the ceiling at the front of the booth and moves diagonally towards the rear and downward, enhancing paint quality by minimizing dust and overspray accumulation on the painted surface.

Balance of Cost and Quality: Offers a balance between the cost-effectiveness of cross draft and the superior finish quality of full down-draft systems.

Cross Draft

Cost Efficiency: Cross draft booths are typically less expensive to build and install since they require simpler ductwork and fewer fans.

Even Airflow: Air enters through filters at one end of the booth and moves horizontally across the vehicle towards the exhaust at the opposite end, providing even airflow that helps achieve a consistent finish.

Side-draft

Vertical Airflow: Air enters through filters on the side walls and moves horizontally across the work area before exiting through filters on the opposite side, reducing the chances of contaminants settling on wet surfaces.

Enhanced Visibility: This setup often provides better lighting and visibility as the airflow supports a cleaner and clearer working environment, essential for precision tasks.

Down-draft

Superior Finish Quality: Air enters from the ceiling and moves downward over the object, exiting through the floor. This vertical airflow pattern helps carry contaminants and overspray away from the vehicle, resulting in a cleaner and higher-quality finish.

Reduced Contamination: The downward flow reduces the likelihood of dust or particles settling on the surface during painting, which is crucial for achieving a flawless finish.

Paint Booth Accessories

Paint Booth Accessories

Best Automotive Paint Booths For Sale

Premier Series Booths

Power Series Booths

Globally Successful Junair Series Booths

Thermaire Series Booths

High efficiency convection ovens

Spray Tech engineers and builds drying and curing ovens to provide excellent temperature uniformity around the part profile throughout the heating process for both liquid and powder curing applications. Any of the components and subassemblies used in our ovens are selected for NFPA compliance, quality and long life. All electrical and mechanical components are widely represented for local service and maintenance.

All oven panels, duct work and heater cabinets are designed by Spray Tech and manufactured in our factory. Typical oven configurations may include mechanical air seals, gravity seals, quiet entry zones and interior baffles to prevent air mixing near openings. IR pre-heat ovens may be used to gel over powder for applications involving high mass parts.

Oven Body Construction

- All oven panels are fabricated on Spray Tech’s own panel manufacturing line.

- Low heat transfer, 6” oven panels for minimal thermal heat loss and increased energy savings.

- Oven floor panels are designed to reduce heat sinking and cold spots and to allow maintenance foot traffic without deforming.

- Ovens are built in sections for shipping and reduced installation time.

- Painted ovens are sometimes provided for an aesthetically appealing appearance.

Oven Burner Systems

- Industry-best packaged burners with high turndown ratios are used for fast and efficient heating.

- Heater cabinets are made with lower gauge aluminized steel and a heavy -duty structural framework to accommodate the recirculating fan and drive.

- High density mineral wool is used in heater cabinet walls to compensate for higher interior operating temperatures.

Duct Work

- All sheet metal work is laser cut and precision made in our shop using computer aided manufacturing tools.

- Aluminized steel is used to prevent distortion due to heating effects and to resist premature corrosion.

- Nozzles are adjustable and fabricated to provide a wide range of air velocity into the oven zone.

- Supply nozzles allow for air flow adjustment, which is necessary for optimizing temperature uniformity.

- Return duct work provides precise control of air flow so that air may be directed where it is required for uniformity performance.

- Typical cure ovens are configured with

- Drying ovens are typically designed for high velocity delivery of air for fast and efficient drying.

- Full recirculating filtration may be included for applications demanding higher finish quality standards.

Oven Controls

- Oven control screens are accessible from the main system PLC and HMI and are designed to minimize the requirement for operator control.

- Ovens are managed locally through sophisticated PID controllers, designed to bring up and maintain oven temperature without overshoot.

- Oven bring up and shut down may be automated.

- Oven performance data may be stored and shared via internet connection.

- All ovens comply with NFPA regulations governing ovens and furnaces for safety, including automated purge, exhaust and explosion relief.

Product Brochures

See Related products

See Related Products

get pricing or connect with the support team.

If you are looking for a Quick Estimate on any of our products, please fill out the short form below so our sales team can help you with pricing.

Where to find us?

- 1427 N. Linden Ave. Rialto, CA

- (909) 419 7011

- sales@spraytech.com