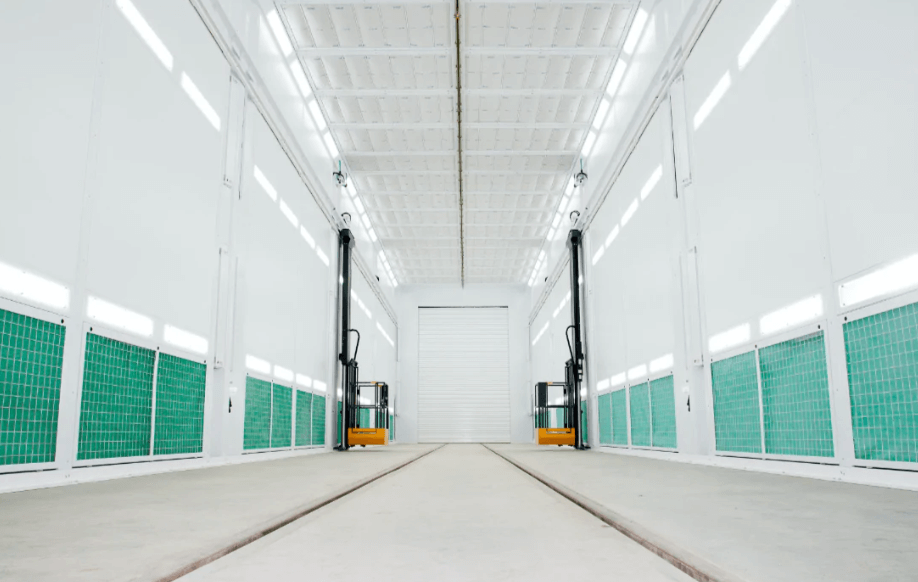

Large Equipment Paint Booths

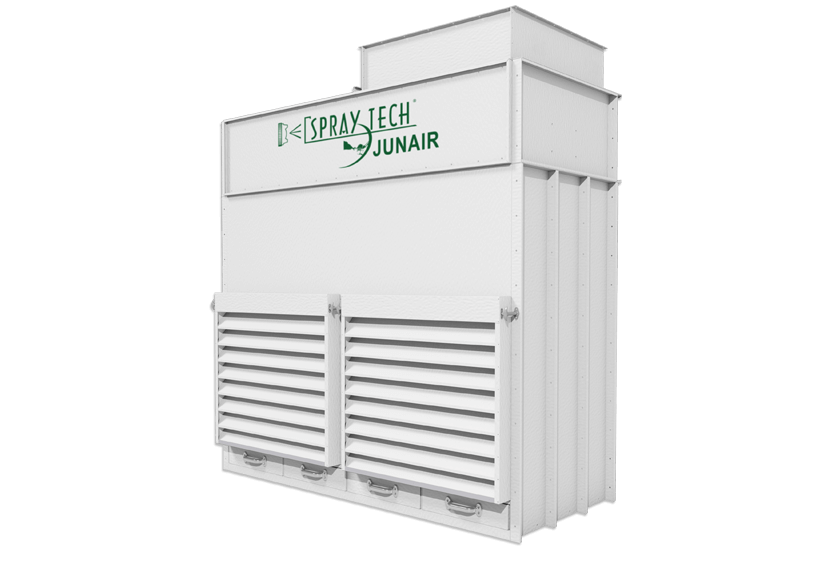

Spray-Tech provides large equipment paint booths that cater to a wide array of industries. We offer customized solutions for projects of any scale. Our booths are designed with cutting-edge technology and high-quality materials to ensure durability, efficiency, and superior finishes.

Large Equipment Paint Booths

Spray-Tech provides large equipment paint booths that cater to a wide array of industries. We offer customized solutions for projects of any scale. Our booths are designed with cutting-edge technology and high-quality materials to ensure durability, efficiency, and superior finishes.

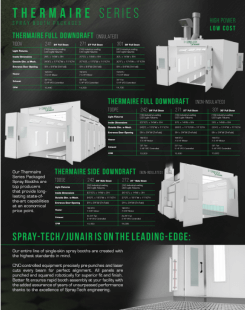

Product Specifications

Product Specifications

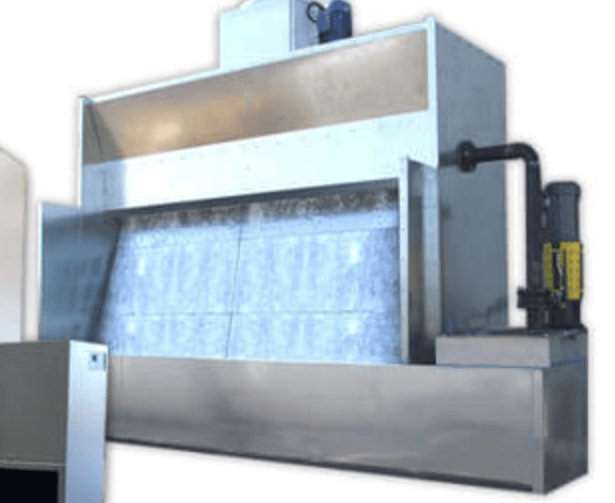

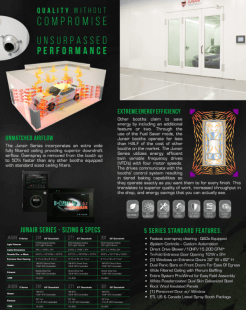

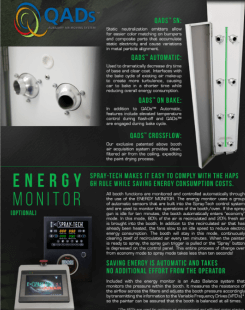

Customize Your Airflow

Reverse flow, side downdraft, full downdraft, and front flow airflow options are available

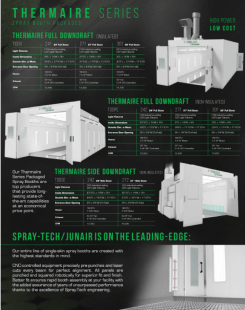

Select Your Product Line

We offer a variety of paint booth models, including our Junair, Premier, and Thermaire models

Controls

Standard features include user programmable controls, allowing unparalleled process customization utilizing PLC and HMI technologies through a simpleto-use touch screen interface.

Construction

Constructed with 18 gauge galvanized steel. Includes double layer 14-gauge stiffeners assembled with carriage bolts.

Doors

All personnel doors are placed per code, double skinned with UL listed fire door frames and include large tempered glass windows.

Code Compliance

Safety and code compliance is our top priority, guiding the design of every paint booth we offer.

Truck Paint Booths

Our state-of-the-art truck paint booth enclosures mark a cutting edge modern design. It will ensure a superior fit and finish, and rapid erection of your booth. We make sure that our truck paint booths are manufactured to reduce maximum energy costs using best engineering practices.

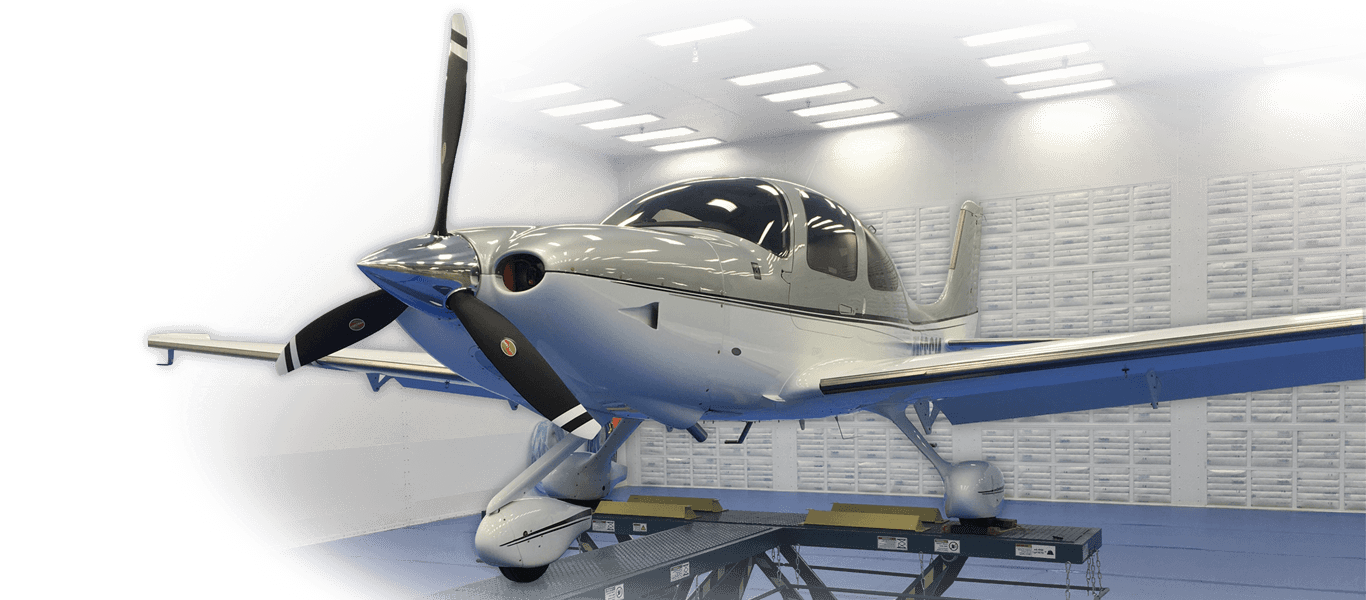

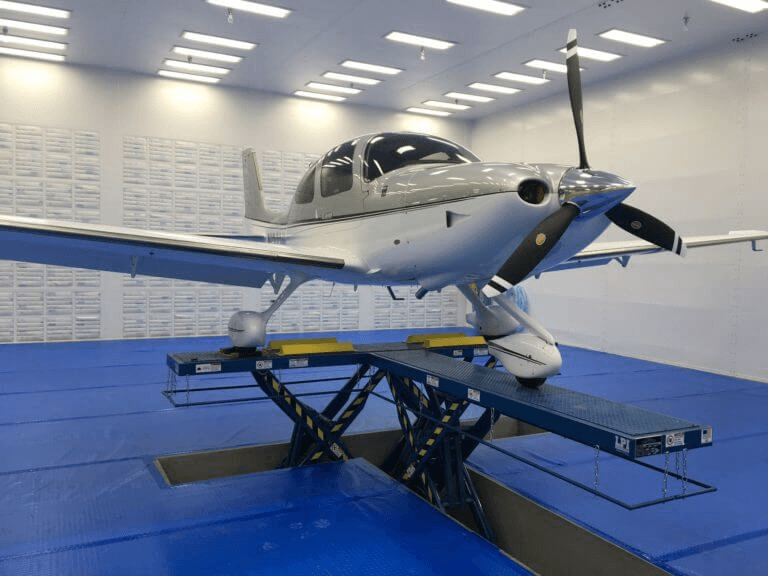

Aircraft Paint Booths

Whether you’re working on a private jet, a commercial airliner, or a historic warbird, we have the paint booth solution to match your needs. Our team collaborates closely with you to understand your specific requirements and craft a paint booth that maximizes efficiency and safety.

Truck paint Booths

Our state-of-the-art truck paint booth enclosures mark a cutting edge modern design. It will ensure a superior fit and finish, and rapid erection of your booth. We make sure that our truck paint booths are manufactured to reduce maximum energy costs using best engineering practices.

AIRCRAFT PAINT BOOTHS

Whether for small aircraft or large commercial jets, our booths offer the ideal controlled environment for superior paint application. When you choose Spray Tech, you choose reliability and top-notch performance for all your aircraft painting requirements.

Farm Equipment & Wind power Stations

We create premium paint booths designed for the specific requirements of farm equipment and wind power stations. Our use of advanced technology and high-quality materials ensures each booth is both durable and efficient, suitable for heavy-duty painting applications. These specialized booths are engineered to provide a superior finish, enhancing the longevity and performance of your equipment.

Whether for small aircraft or large commercial jets, our booths offer the ideal controlled environment for superior paint application. When you choose Spray Tech, you choose reliability and top-notch performance for all your aircraft painting requirements.

Farm Equipment & Wind Power Stations

We create premium paint booths designed for the specific requirements of farm equipment and wind power stations. Our use of advanced technology and high-quality materials ensures each booth is both durable and efficient, suitable for heavy-duty painting applications. These specialized booths are engineered to provide a superior finish, enhancing the longevity and performance of your equipment.

Boat Paint Booths

Spray-Tech now offers specialized boat paint booths, designed to accommodate the unique needs of the marine industry. Our boat paint booths are crafted with precision, using advanced technology and superior materials to ensure a perfect finish for a variety of marine vessels. These booths are engineered to handle the intricacies of boat painting, from small leisure crafts to large commercial vessels, providing efficient, durable, and high-quality results.

Custom Airflow Options

Semi Down-Draft

Improved Airflow Pattern: Air enters through the ceiling at the front of the booth and moves diagonally towards the rear and downward, enhancing paint quality by minimizing dust and overspray accumulation on the painted surface.

Balance of Cost and Quality: Offers a balance between the cost-effectiveness of cross draft and the superior finish quality of full down-draft systems.

Cross Draft

Cost Efficiency: Cross draft booths are typically less expensive to build and install since they require simpler ductwork and fewer fans.

Even Airflow: Air enters through filters at one end of the booth and moves horizontally across the vehicle towards the exhaust at the opposite end, providing even airflow that helps achieve a consistent finish.

Side-draft

Vertical Airflow: Air enters through filters on the side walls and moves horizontally across the work area before exiting through filters on the opposite side, reducing the chances of contaminants settling on wet surfaces.

Enhanced Visibility: This setup often provides better lighting and visibility as the airflow supports a cleaner and clearer working environment, essential for precision tasks.

Down-draft

Superior Finish Quality: Air enters from the ceiling and moves downward over the object, exiting through the floor. This vertical airflow pattern helps carry contaminants and overspray away from the vehicle, resulting in a cleaner and higher-quality finish.

Reduced Contamination: The downward flow reduces the likelihood of dust or particles settling on the surface during painting, which is crucial for achieving a flawless finish.

Prioritizing Safety

Prioritizing Safety

Our commitment to safety aligns with OSHA’s guidelines and regulations, ensuring a secure working environment for all.

Spray-Tech is committed to upholding and advancing the rigorous safety measures advocated by NFPA to ensure a secure and compliant environment for our clients.

We work hard to meet ETL standards in order to ensure our electrical equipment meets rigorous safety and performance criteria.

Our environmental responsibility is reflected in our compliance with EPA regulations, contributing to a cleaner and sustainable future.

Paint Booth Accessories

See Related products

See Related Products

Product Brochures

We are happy to help you learn about our new products, get pricing, or connect you with the support team.

If you are looking for a Quick Estimate on any of our products, please fill out the short form below so our sales team can help you with pricing.

Where to find us?

- 1427 N. Linden Ave. Rialto, CA

- +1 (800) 535 8196

- +1 (800) 535 8196

- sales@spraytech.com