Industrial Finishing Batch Systems

INDUSTRIAL FINISHING BATCH SYSTEMS

Spray Tech designs and fabricates custom batch finishing systems for lower volume production requirements. System options include manual, semi-automatic or full indexing. Spray Tech provides batch ovens, pretreatment washers, and conveyors. We include field installation and start up for a complete turnkey system.

Batch systems handle lower production requirements and unique products. Using overhead conveyor options increase production over standard batch carts. Manually conveyorized batch lines reduce labor hours and cost less to operate.

Spray Tech designs and fabricates custom batch finishing systems for lower volume production requirements. System options include manual, semi-automatic or full indexing. Spray Tech provides batch ovens, pretreatment washers, and conveyors. We include field installation and start up for a complete turnkey system.

Batch systems handle lower production requirements and unique products. Using overhead conveyor options increase production over standard batch carts. Manually conveyorized batch lines reduce labor hours and cost less to operate.

500 Degree Batch Ovens

500 Degree Batch Ovens

Overview: Spray Tech builds custom batch ovens with the same industry expertise as our continuous ovens. Ovens are custom designed for specific applications. Part size and production volumes dictate oven and system configuration. Ovens are equipped with air heat burners and standard PID controllers for precise temperature control. Supply and return duct work and adjustable nozzles ensure excellent heat temperature uniformity and heating rates. Spray Tech ovens are constructed for low maintenance and long service life. Ovens are configured in a variety of sizes to suit customer process requirements.

Features include:

Overview: Spray Tech builds custom batch ovens with the same industry expertise as our continuous ovens. Ovens are custom designed for specific applications. Part size and production volumes dictate oven and system configuration. Ovens are equipped with air heat burners and standard PID controllers for precise temperature control. Supply and return duct work and adjustable nozzles ensure excellent heat temperature uniformity and heating rates. Spray Tech ovens are constructed for low maintenance and long service life. Ovens are configured in a variety of sizes to suit customer process requirements.

Features include:

- Six-inch panels reduce heat loss and save energy.

- Heavy internal structural steel frame supports oven body and heater cabinet.

- Manual swing doors or with automatic door operators.

- Duct work is laser cut and precision formed. Louvered supply and return ducts for precise temperature control.

- Industrial proportioning burners and best-in-class gas train components.

- PID proportioning controllers to optimize temperature control and prevent overshoot.

- Tight uniformity to meet both powder or liquid coating specifications.

- Recirculating air filtration options.

- Six-inch panels reduce heat loss and save energy.

- Heavy internal structural steel frame supports oven body and heater cabinet.

- Manual swing doors or with automatic door operators.

- Duct work is laser cut and precision formed. Louvered supply and return ducts for precise temperature control.

- Industrial proportioning burners and best-in-class gas train components.

- PID proportioning controllers to optimize temperature control and prevent overshoot.

- Tight uniformity to meet both powder or liquid coating specifications.

- Recirculating air filtration options.

Spray Tech builds custom batch ovens with the same industry expertise as our continuous ovens. Ovens are custom designed for specific applications. Part size and production volumes dictate oven and system configuration. Ovens are equipped with air heat burners and standard PID controllers for precise temperature control. Supply and return duct work and adjustable nozzles ensure excellent heat temperature uniformity and heating rates.

Spray Tech ovens are constructed for low maintenance and long service life. Ovens are configured in a variety of sizes to suit customer process requirements. Features include:

- Six-inch panels reduce heat loss and save energy.

- Heavy internal structural steel frame supports oven body and heater cabinet.

- Manual swing doors or with automatic door operators.

- Duct work is laser cut and precision formed. Louvered supply and return ducts for precise temperature control.

- Industrial proportioning burners and best-in-class gas train components.

- PID proportioning controllers to optimize temperature control and prevent overshoot.

- Tight uniformity to meet both powder or liquid coating specifications.

- Recirculating air filtration options.

Batch Cycle Washers

Batch Cycle Washers

Overview: Spray Tech batch cycle washers are designed to simulate full production automated washers. Products are advanced into an enclosed housing and then processed through multiple chemical and rinse stages to prepare the substrate material. Chemical and rinse tanks are included so that chemical and water rinses may be recirculated to conserve chemical and water use. Through a system PLC, the washer automatically cycles through these multiple stages while giving the product a full coverage pretreatment. Cycle washers reduce manual labor and provide a consistent, repeatable pre-treatment performance.

Batch washers are shipped in large, assembled sections for faster field installation.

Product Features:

- Constructed of 304 Stainless Steel with optional 316 Stainless on acidic stages

- Heavy external structural steel framing supports walls and product conveyor

- Manual articulating doors or automatic door operators.

- Stainless steel water tanks equipped with optional oil removal, filtration, and chemical injection systems

- Industrial proportioning burners and best-in-class gas train components.

- PID proportioning controllers to optimize temperature control and prevent overshoot.

- Tight uniformity to meet both powder or liquid coating specifications.

- Optional reverse osmosis system for rinse tanks & wetting halo

Overview: Spray Tech batch cycle washers are designed to simulate full production automated washers. Products are advanced into an enclosed housing and then processed through multiple chemical and rinse stages to prepare the substrate material. Chemical and rinse tanks are included so that chemical and water rinses may be recirculated to conserve chemical and water use. Through a system PLC, the washer automatically cycles through these multiple stages while giving the product a full coverage pretreatment. Cycle washers reduce manual labor and provide a consistent, repeatable pre-treatment performance.

Batch washers are shipped in large, assembled sections for faster field installation.

Product Features:

- Constructed of 304 Stainless Steel with optional 316 Stainless on acidic stages

- Heavy external structural steel framing supports walls and product conveyor

- Manual articulating doors or automatic door operators.

- Stainless steel water tanks equipped with optional oil removal, filtration, and chemical injection systems

- Industrial proportioning burners and best-in-class gas train components.

- PID proportioning controllers to optimize temperature control and prevent overshoot.

- Tight uniformity to meet both powder or liquid coating specifications.

- Optional reverse osmosis system for rinse tanks & wetting halo

Batch Manual Washers

Batch Manual Washers

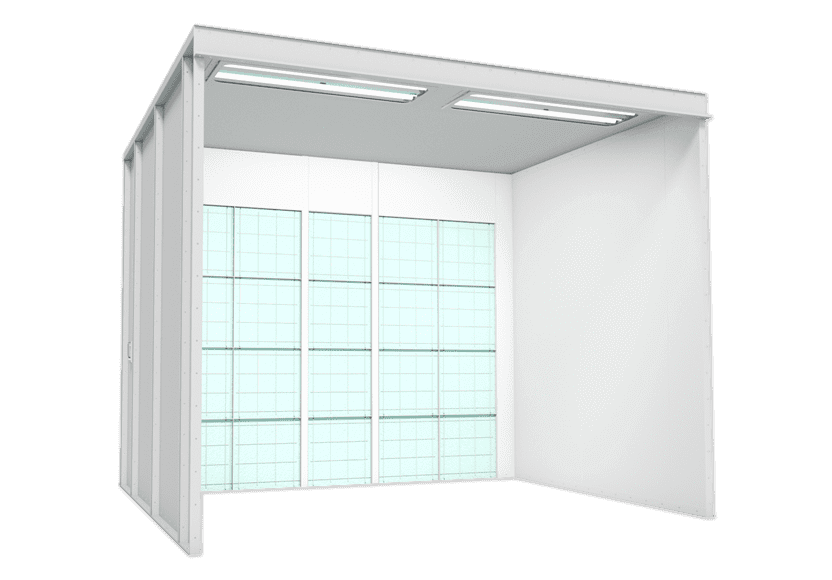

Overview: Manual spray booths are used as an entry level pre-treatment option for batch liquid and powder coating operations. A manual booth may also be used by larger production shops for parts too big for the main wash line or for special assemblies. For this type of washer, the chemical feed may be recirculated through the main washer for a consistent and reliable pre-treatment.

Spray-Tech manual washers include a wash booth and lighting, a heated wand, and a grated floor. The booth is designed so that operators are free to walk around parts as they spray. The discharge can be set up to go straight to sewer, or the washer floor may be designed to collect and treat effluent for sludge and pH adjustment before draining.

Product Features:

- Batch manual washers are made from stainless steel or corrosion resistant clear poly side walls.

- Heated, multi-stage spray wands are commercially available and serviceable by Spray Tech and its local affiliates.

- Exterior booth structures are painted to resist corrosion and for an attractive appearance.

- Ancillary options are available, such as RO systems, filtration, and local waste treatment.

- The discharge can be set up to go straight to the sewer.

- Washer floor may be designed to collect and treat effluent for sludge and pH adjustment before draining.

Overview: Manual spray booths are used as an entry level pre-treatment option for batch liquid and powder coating operations. A manual booth may also be used by larger production shops for parts too big for the main wash line or for special assemblies. For this type of washer, the chemical feed may be recirculated through the main washer for a consistent and reliable pre-treatment.

Spray-Tech manual washers include a wash booth and lighting, a heated wand, and a grated floor. The booth is designed so that operators are free to walk around parts as they spray. The discharge can be set up to go straight to sewer, or the washer floor may be designed to collect and treat effluent for sludge and pH adjustment before draining.

Product Features:

- Batch manual washers are made from stainless steel or corrosion resistant clear poly side walls.

- Heated, multi-stage spray wands are commercially available and serviceable by Spray Tech and its local affiliates.

- Exterior booth structures are painted to resist corrosion and for an attractive appearance.

- Ancillary options are available, such as RO systems, filtration, and local waste treatment.

- The discharge can be set up to go straight to the sewer.

- Washer floor may be designed to collect and treat effluent for sludge and pH adjustment before draining.

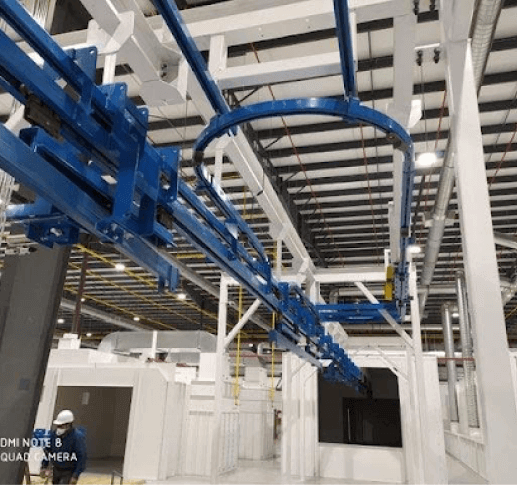

Batch System Conveyor Ovens

Batch System Conveyor Ovens

Overview: Spray Tech provides layout options to help optimize product workflow. Powered and non-powered enclosed track or I-beam conveyors are used to transport products throughout the batch system from pre-treatment through unloading. Transporting parts on overhead conveyors reduces labor significantly over conventional batch carts.

Conveyors are designed to move parts efficiently. In addition, conveyor queues are used for cooling, loading, unloading and masking. Once the product or rack of parts goes on line in the load area, it doesn’t come off again until unload. Our customers have found that automating their batch finishing process has increased production by as much as 50% over the use of batch carts.

Product Features:

Overview: Spray Tech provides layout options to help optimize product workflow. Powered and non-powered enclosed track or I-beam conveyors are used to transport products throughout the batch system from pre-treatment through unloading. Transporting parts on overhead conveyors reduces labor significantly over conventional batch carts.

Conveyors are designed to move parts efficiently. In addition, conveyor queues are used for cooling, loading, unloading and masking. Once the product or rack of parts goes on line in the load area, it doesn’t come off again until unload. Our customers have found that automating their batch finishing process has increased production by as much as 50% over the use of batch carts.

Product Features:

- Automatic or indexing conveyors. Push-pull manual conveyor systems.

- PLCs automate indexing conveyors. Operator involvement is minimal.

- Enclosed track or I-beam conveyors for varying load requirements.

- Floor mounted or overhead conveyor supports.

- Heavy duty track and trolleys for long service life and low maintenance.

- Automatic or indexing conveyors. Push-pull manual conveyor systems.

- PLCs automate indexing conveyors. Operator involvement is minimal.

- Enclosed track or I-beam conveyors for varying load requirements.

- Floor mounted or overhead conveyor supports.

- Heavy duty track and trolleys for long service life and low maintenance.

Installation & Start-Up

The Spray Tech Finishing Systems Group handles all the project management and coordination for batch systems from engineering through start up. Once the project is underway, Spray Tech engineers design the system for customer approval. All major batch system components are designed and manufactured in the Spray Tech facility. This single-source responsibility assures a smooth and successful project launch.

Once the equipment is installed, a Spray Tech start-up engineer makes an on-site visit to debug and start up the equipment. In addition to start up, Spray Tech technicians also make on-going visits for service and system checks through our Vendor Managed Inventory (VMI) program

- Spray Tech engineer oversees and manages project from engineering through start-up.

- Direct Spray Tech personnel on site for installation.

- Spray Tech technician performs start up and de-bugging.

- Spray Tech provides a comprehensive list of spare parts for all equipment.

- Quarterly system check and preventative maintenance by authorized Spray Tech technician.

get pricing or connect with the support team.

get pricing or connect with the support team.

If you are looking for a Quick Estimate on any of our products, please fill out the short form below so our sales team can help you with pricing.

Installation & Start Up

The Spray Tech Finishing Systems Group handles all the project management and coordination for batch systems from engineering through start up. Once the project is underway, Spray Tech engineers design the system for customer approval. All major batch system components are designed and manufactured in the Spray Tech facility. This single-source responsibility assures a smooth and successful project launch.

Once the equipment is installed, a Spray Tech start-up engineer makes an on-site visit to debug and start up the equipment. In addition to start up, Spray Tech technicians also make on-going visits for service and system checks through our Vendor Managed Inventory (VMI) program

- Spray Tech engineer oversees and manages project from engineering through start-up.

- Direct Spray Tech personnel on site for installation.

- Spray Tech technician performs start up and de-bugging.

- Spray Tech provides a comprehensive list of spare parts for all equipment.

- Quarterly system check and preventative maintenance by authorized Spray Tech technician.

See Related products

See Related Products

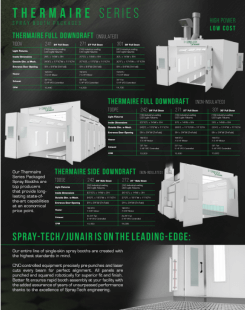

Powder Coating Booths

Upgrade your finishing process with our state-of-the-art powder coating booths.

Convection ovens

We specialize in crafting a wide range of custom power coating ovens, including conveyor belt systems and batch ovens.