Spray-Tech Finishing Systems Group

The Spray-Tech Finishing Systems Group designs, fabricates and installs turnkey finishing systems across a wide range of industries. As part of the Spray-Tech/Junair company of products, the Finishing Systems Group operates as a separate business unit with a dedicated staff of engineers, installation personnel, and start-up technicians. Manufacturers all over North America depend on Spray-Tech liquid and powder coating lines for finishing anything from office furniture to skid steer loaders.

Our Finishing Systems Products

Environmental Rooms

We oversee every step of the manufacturing process from design through installation.

High Efficiency Convection Ovens

Spray Tech engineers and builds drying and curing ovens to provide excellent temperature uniformity around the part profile throughout the heating process for both liquid and powder curing applications.

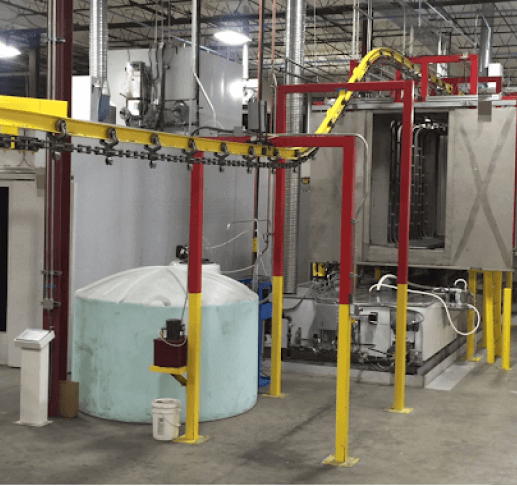

Pre-Treatment Washer

The integrity of the paint finishing process begins with pre-treatment. It is the first step in the finishing line, and it’s critical to the outcome of the final paint quality.

Advanced Modular Systems

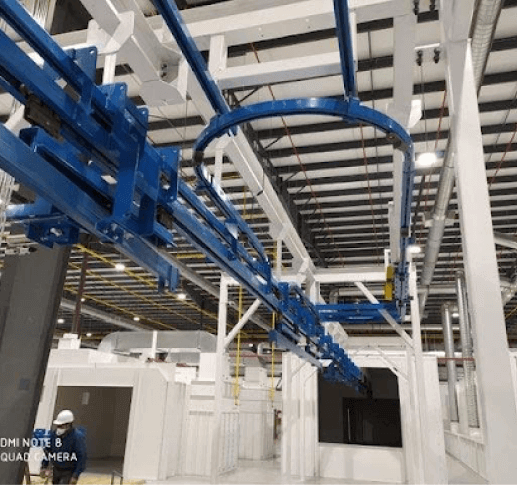

Equipment ships in modular assemblies, pre-wired and pre-plumbed to whatever extent possible to minimize field assembly time. UL electrical panels are pre-wired with all system components, such as flame circuitry, motor starters, frequency drives and control instrumentation. Once shipped to the jobsite, the only requirement is to drop power into the control cabinet and run interconnecting wire to specific components, such as fan motors and burners. Wiring looms are used to cut field electrical time significantly.

Washers and ovens are pre-assembled in large modules to eliminate field hours and speed up delivery. Gas burner trains are completely pre-plumbed and wired to junction boxes for simple field wiring. Conveyor supports are welded and assembled with pre-drilled bases for fast installation.

State-of-the-Art Manufacturing

Spray-Tech is committed to state-of-the-art computer aided design and computer aided manufacturing technology. Advanced engineering CAD software is used for design and simulation of system components. High-volume, computer-controlled manufacturing equipment is used to cost efficiently produce precision components while minimizing waste.

Industry Advantages

Spray-Tech/Junair manufactures a high volume of sheet metal products - and we do it efficiently. Spray booths, powder booths, oven panels, environmental rooms – and paint finishing systems - are all built in our central manufacturing facility. This economy of scale allows us to fabricate our system components cost efficiently using best-in-class, computer-aided manufacturing equipment.

Excellent Supplier Relationships

Spray-Tech vets its suppliers very carefully through a comprehensive qualification process. Supplier partners are selected not only for quality, price, and delivery, but also for their commitment to local service. Major system sub-components, such as pumps, burners, motors, and electrical components are typically supported by local distributors and service centers.

Trained Field Personnel and Direct Employees

Spray-Tech uses a combination of its own employees and trusted contractors for system installations. Controls and PLC implementation is done by Spray-Tech controls engineers, and programming changes may be handled remotely from our office. Start-up and training is provided by direct Spray-Tech start-up technicians and engineers.

Energy Conservation Technology

The Spray-Tech builds systems that are designed to save energy. At Spray-Tech, energy conservation isn’t just a concept. The Spray-Tech facility itself incorporates many energy saving technologies. We believe saving energy and utility costs has universal application, and these energy cost saving ideas are built into the equipment we provide.

Many of the energy saving features of our systems are used by customers to reduce their capital expense by applying for energy rebates from their local utility suppliers. During this process Spray-Tech engineers work with our customers, providing justification and support for energy rebates.

get pricing or connect with the support team.

If you are looking for a Quick Estimate on any of our products, please fill out the short form below so our sales team can help you with pricing.

Where to find us?

- 1427 N. Linden Ave. Rialto, CA

- (909) 419 7011

- sales@spraytech.com