Paint Finishing Pretreatment Washers

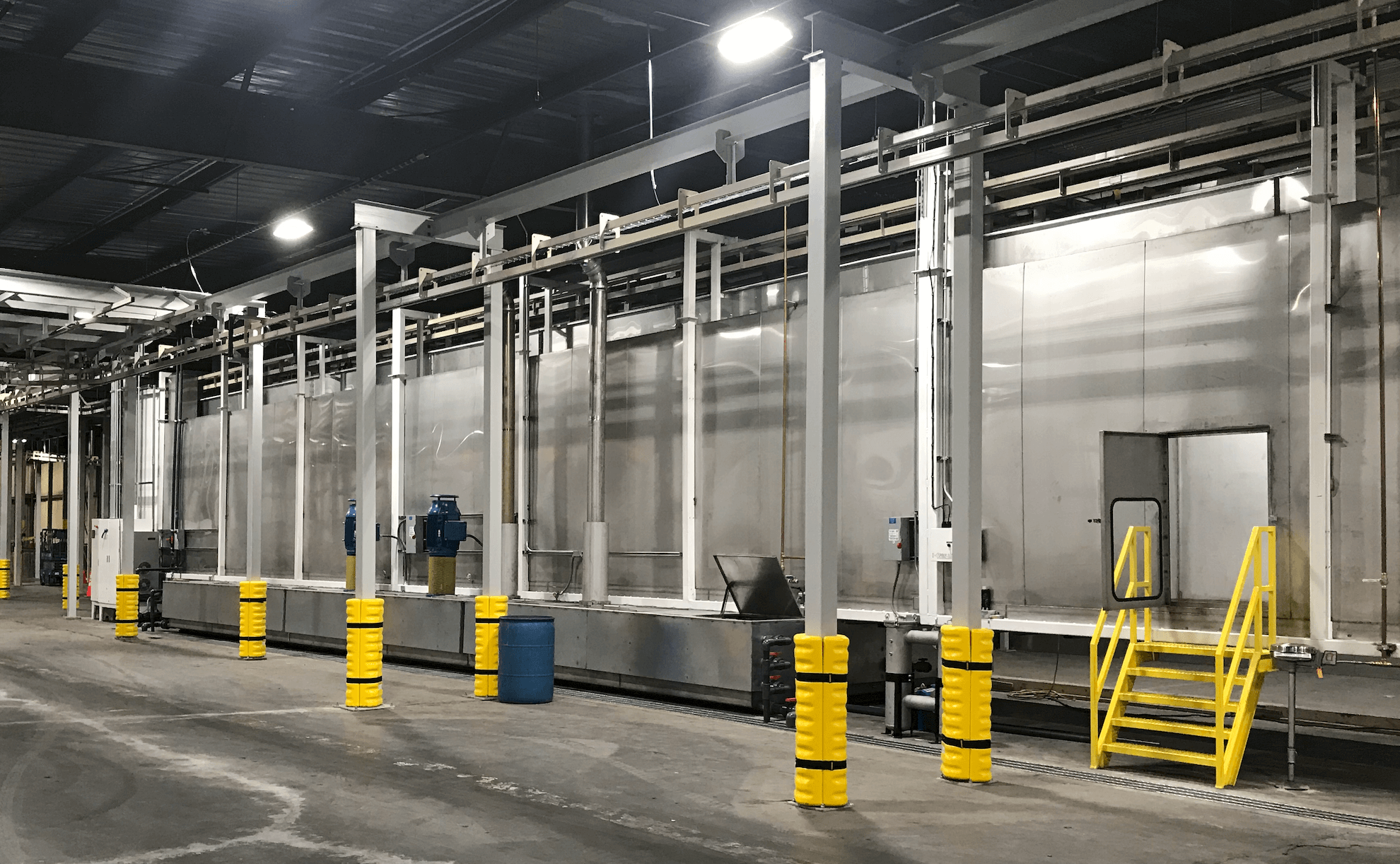

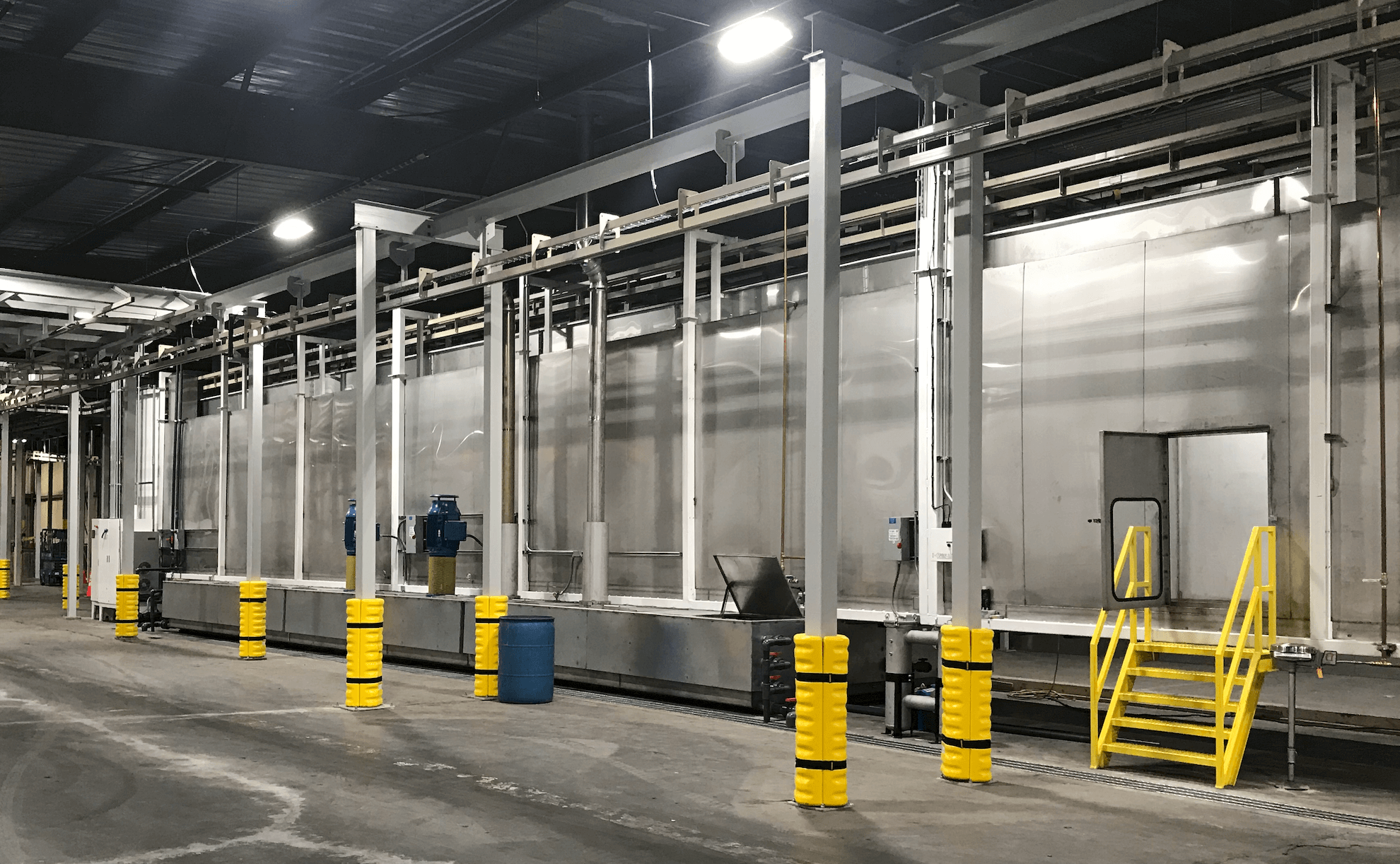

The integrity of the paint finishing process begins with pre-treatment. It is the first step in the finishing line, and it’s critical to the outcome of the final paint quality. Chemical spray stages clean and coat the metal substrate as preparation for paint. Paint adhesion depends on a clean and thoroughly prepared substrate. Spray Tech pre-treatment washers save energy and lower operating costs

Paint Finishing Pre-Treatment Washers

The integrity of the paint finishing process begins with pre-treatment. It is the first step in the finishing line, and it’s critical to the outcome of the final paint quality. Chemical spray stages clean and coat the metal substrate as preparation for paint. Paint adhesion depends on a clean and thoroughly prepared substrate. Spray Tech pre-treatment washers save energy and lower operating costs

Pretreatment Washer Design

Pretreatment Washer Design

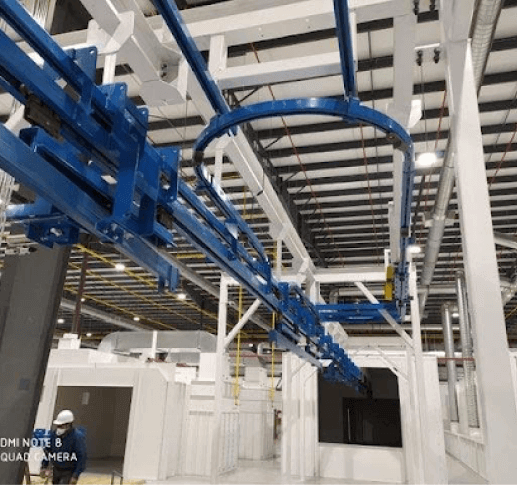

Product Overview: Spray Tech automated washers are efficient and consume less energy. Key design features include safe maintenance access, quick installation, and long service life. Spray Tech uses only best-in-class components. We select components for long service life, and we choose suppliers that offer local support. Every pre-treatment system meets chemical supplier specifications. Stage times, temperatures and material specifications are strictly adhered to.

Spray Tech washer modules are assembled, pre-plumbed and tested in our shop before shipping to streamline installation. Tanks are double welded and tested for leaks for this same purpose. This speeds up field installation and limits downtime.

Washer headers are stainless and self-draining. Stainless headers eliminate the common problems of splitting and warping with CPVC or PVC headers. Risers may be fabricated from PVC, CPVC or stainless, depending on the application.

Pump materials are selected to match chemical supplier recommendations. High efficiency motors are used to lower operational costs. All control panels are UL labeled to eliminate the need for field certification.

Product Features:

Product Overview: Spray Tech automated washers are efficient and consume less energy. Key design features include safe maintenance access, quick installation, and long service life. Spray Tech uses only best-in-class components. We select components for long service life, and we choose suppliers that offer local support. Every pre-treatment system meets chemical supplier specifications. Stage times, temperatures and material specifications are strictly adhered to.

Spray Tech washer modules are assembled, pre-plumbed and tested in our shop before shipping to streamline installation. Tanks are double welded and tested for leaks for this same purpose. This speeds up field installation and limits downtime.

Pump materials are selection to match chemical supplier recommendations. High efficiency motors are used to lower operational costs. All control panels are UL labeled to eliminate the need for field certification.

Washer headers are stainless and self-draining. Stainless headers eliminate the common problems of splitting and warping with CPVC or PVC headers. Risers may be fabricated from PVC, CPVC or stainless, depending on the application.

Product Features:

- Washer housings and tanks are continuously welded to provide structural support and to prevent leaks.

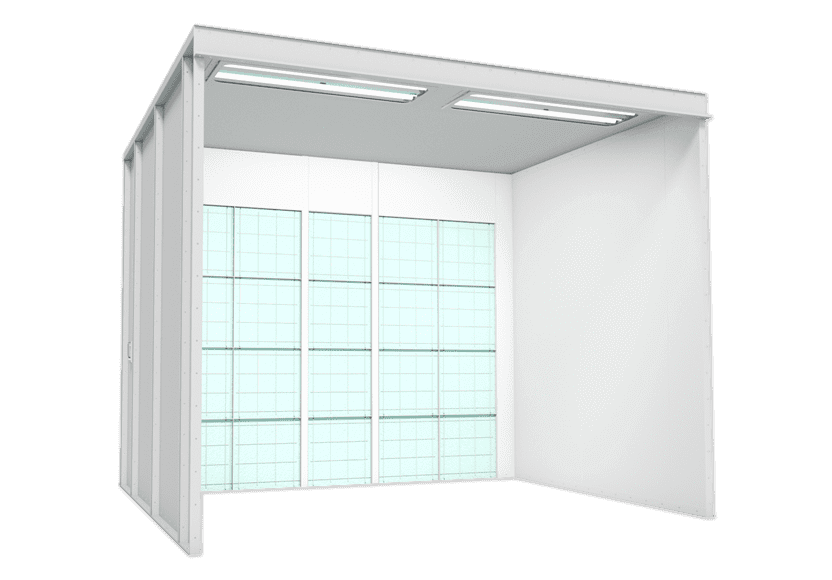

- Housings are offered in closed or split top design.

- Ladders and handrails to each stage. Windows in stage doors & lights throughout the washer for inspection & maintenance.

- Insulated hot tanks and energy saving packages for housings.

- Stainless steel mist eliminators to separate heavy mist from the exhaust stream.

- Packaged proportioning burners and heat exchangers built to the manufacturer’s exact specifications.

- Automated counter flowing for chemical conservation and to minimize water consumption.

- Washer components are best-in-class and represented by local service groups and distributors. Pumps, fans, controls, valves, fans, and nozzles are all supported by Spray Tech and its local affiliates.

- Washer housings and tanks are continuously welded to provide structural support and to prevent leaks.

- Housings are offered in closed or split top design.

- Ladders and handrails to each stage. Windows in stage doors & lights throughout the washer for inspection & maintenance.

- Insulated hot tanks and energy saving packages for housings.

- Stainless steel mist eliminators to separate heavy mist from the exhaust stream.

- Packaged proportioning burners and heat exchangers built to the manufacturer’s exact specifications.

- Automated counter flowing for chemical conservation and to minimize water consumption.

- Washer components are best-in-class and represented by local service groups and distributors. Pumps, fans, controls, valves, fans, and nozzles are all supported by Spray Tech and its local affiliates.

High efficiency Washers

High Efficiency Washers

Operating pre-treatment washers can be costly. Spray Tech helps to lower operating costs through design. Using high efficiency components and added control features keep costs down. Our engineering focus is on lowering energy costs and reducing maintenance expenses through automated control features. PLCs control ancillary processes, such as blow-off and reverse osmosis systems, to minimize operating costs.

Spray Tech will work with local municipalities to determine if energy saving features qualify for rebates or credits. High-efficiency motors, high-efficiency burners, and energy saving packages often qualify for energy credits.

Energy and Cost Saving Features:

- Automated continuous monitoring and control without operator intervention reduces labor and maintains process integrity.

- Auto chemical monitoring and delivery to keep chemical balances within specified range and reduce labor.

- High efficiency motors and burners for reduction of energy use.

- Pump pressures are controlled through motor VFD for best-practice pump performance and energy cost reduction.

- Energy insulating packages for washer tanks and housings.

- Automated counter flow systems for reducing use of costly chemicals and for water conservation.

- Oil separation systems and filtration for chemical conservation. Extends bath life, reduces sludge and keeps nozzles clean.

Operating pre-treatment washers can be costly. Spray Tech helps to lower operating costs through design. Using high efficiency components and added control features keep costs down. Our engineering focus is on lowering energy costs and reducing maintenance expenses through automated control features. PLCs control ancillary processes, such as blow-off and reverse osmosis systems, to minimize operating costs.

Spray Tech will work with local municipalities to determine if energy saving features qualify for rebates or credits. High-efficiency motors, high-efficiency burners, and energy saving packages often qualify for energy credits.

Energy and Cost Saving Features:

- Automated continuous monitoring and control without operator intervention reduces labor and maintains process integrity.

- Auto chemical monitoring and delivery to keep chemical balances within specified range and reduce labor.

- High efficiency motors and burners for reduction of energy use.

- Pump pressures are controlled through motor VFD for best-practice pump performance and energy cost reduction.

- Energy insulating packages for washer tanks and housings.

- Automated counter flow systems for reducing use of costly chemicals and for water conservation.

- Oil separation systems and filtration for chemical conservation. Extends bath life, reduces sludge and keeps nozzles clean.

Easy to use features

Easy To Use Features

Spray Tech washers are built with state-of-the-art, automated controls. The washer control screens are accessible from the main system PLC and HMI. Washer controls limit operator involvement. Washer controls may be configured to monitor and control process variables, such as pressure, temperature, and chemical pH balance. A dedicated control panel is located at the washer and all controls communicate back to the main system PLC.

Spray Tech Washer Automation Features:

- Washer control automation keeps the process simple and repeatable.

- Washer soft start and automated for sequential start up.

- PLC monitoring and control of process variables. Temperature, pressure and pH adjusted and controlled via PLC.

- Data acquisition and storage of key information. SPC control and a digital record of process variables.

- Alarms for exceeding process limits.

- Lock-out features.

- Auto chemical delivery systems through the main PLC.

- Maintenance interval prompts and service indicators.

- Control of pump VFD for energy savings and soft start.

Spray Tech washers are built with state-of-the-art, automated controls. The washer control screens are accessible from the main system PLC and HMI. Washer controls limit operator involvement. Washer controls may be configured to monitor and control process variables, such as pressure, temperature, and chemical pH balance. A dedicated control panel is located at the washer and all controls communicate back to the main system PLC.

Spray Tech Washer Automation Features:

- Washer control automation keeps the process simple and repeatable.

- Washer soft start and automated for sequential start up.

- PLC monitoring and control of process variables. Temperature, pressure and pH adjusted and controlled via PLC.

- Data acquisition and storage of key information. SPC control and a digital record of process variables.

- Alarms for exceeding process limits.

- Lock-out features.

- Auto chemical delivery systems through the main PLC.

- Maintenance interval prompts and service indicators.

- Control of pump VFD for energy savings and soft start.

Get Pricing & Ask Questions

get pricing or connect with the support team.

If you are looking for a Quick Estimate on any of our products, please fill out the short form below so our sales team can help you with pricing.

Contact our sales team for pricing!

See Related products

See Related Products

Batch Systems

We designs and fabricates custom batch finishing systems for lower volume production requirements.

Powder Coating Booths

Upgrade your finishing process with our state-of-the-art powder coating booths.

Convection ovens

We specialize in crafting a wide range of custom power coating ovens, including conveyor belt systems and batch ovens.