INDUSTRIAL FINISHING ENVIRONMENTAL ROOMS

INDUSTRIAL fINISHING ENVIRONMENTAL ROOMS

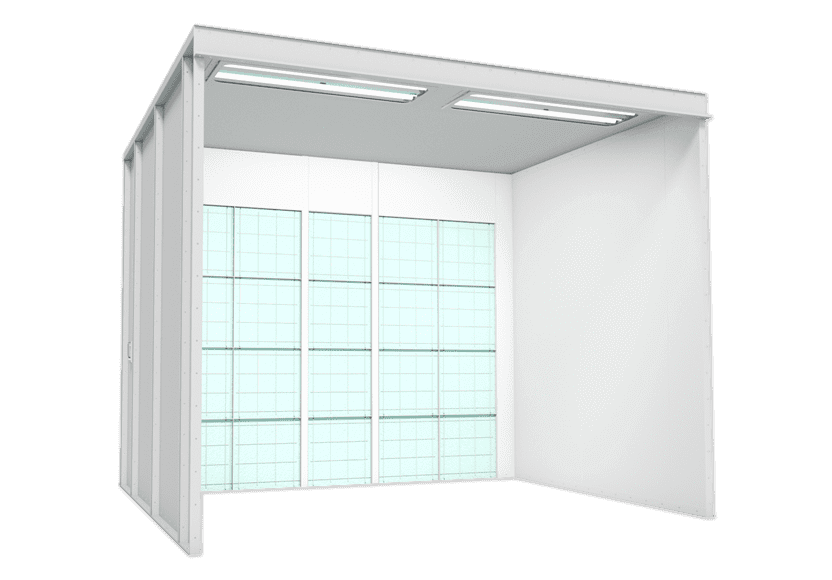

Environmental clean rooms are preferred for any process that demands a clean and air conditioned environment for industrial painting and more. Placing a powder booth inside a clean and positively pressurized Spray Tech Environmental Room reduces the risk of contaminant infiltration while controlling air temperature and humidity. Read more about our Environmental Rooms below or get a project estimate now.

Environmental clean rooms are preferred for any process that demands a clean and air conditioned environment for industrial painting and more. Placing a powder booth inside a clean and positively pressurized Spray Tech Environmental Room reduces the risk of contaminant infiltration while controlling air temperature and humidity. Read more about our Environmental Rooms below or get a project estimate now.

CUSTOMIZATION OPTIONS

E Room Features

We’ll customize your air handling unit based on the size of the room. Chiller size will be determined by the volume of the space, humidity requirement, and the heat load into the room. Our engineers will help determine the HVAC package you need to provide optimal conditions for coating your parts. The HVAC system will be PLC controlled and respond automatically to changing conditions.

We’ll customize the size of your environmental room so that it’s designed for the size of your powder booth and for storage of powder. Rooms can also be built with enough space for a paint lab and an operator workstation. With our custom solutions, your clean room will be optimized for coating efficiency, offering the ideal temperature and humidity environment for your operations.

For shops seeking abundant natural light and an impressive display of their painting application area, we can incorporate additional windows. If utility and functionality take precedence, opting for fewer windows may be the perfect choice. Whatever your preferences, we've got you covered.

Entrance and egress personnel doors are standard on every E Room. We offer large-opening that may be added for transporting powder and equipment into the room. We can also provide rollup doors for which are built for tight spaces and convenience.

Environmental Room Features

E Room Product Details

- The Spray Tech environmental rooms use rigid steel walls and mineral wool insulation.

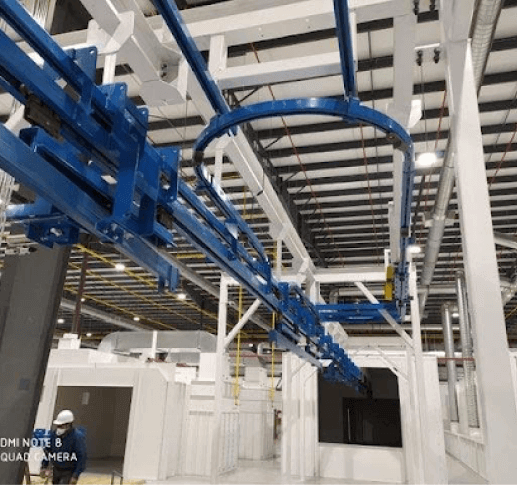

- Designs accommodate any production booth, including quick color change systems.

- Powder coated structural steel trusses for support.

- Rooms are powder coated white for easy cleaning and an attractive appearance.

- Spray Tech manufactures and installs its own LED lighting for its E Rooms.

- Spray Tech engineers the HVAC package and fabricates all necessary distribution duct work.

- High quality, industrial refrigeration packages with a wide range of capacities.

CLEAN ROOM PROPERTIES

- The Spray Tech environmental rooms use rigid steel walls and mineral wool insulation.

- Designs accommodate any production booth, including quick color change systems.

- Powder coated structural steel trusses for support.

- Rooms are powder coated white for easy cleaning and an attractive appearance.

- Spray Tech manufactures and installs its own LED lighting for its E Rooms.

- Spray Tech engineers the HVAC package and fabricates all necessary distribution duct work.

- High quality, industrial refrigeration packages with a wide range of capacities.

PRODUCT DETAILS

- Powder materials are stored in a cool and low RH environment

- Automated pressure controls prevent unwanted contaminants from entering the room

- Operates across E Room controls from the main system HMI screen

- E Rooms may include operator lab rooms and office space for line technicians

- Spray-tech integrates the E Room and provides start-up as part of the overall finishing system package

- The Spray-Tech E Rooms are designed with enough space to store powder material in bulk

- Roll up service doors for bringing in powder material.

- Powder materials are stored in a cool and low RH environment

- Automated pressure controlvs prevent unwanted contaminatns from entering the room

- Operates across E Room controals from the main system HMI screen

- E Rooms may include operator lab rooms and office space for line technicians

- Spray-tech integrates the E Room and provides start-up as part of the overall finishing system package

- The Spray-Tech E Rooms are designed with enough space to store powder material in bulk

- Roll up service doors for bringing in powder material.

get pricing or connect with the support team.

get pricing or connect with the support team.

If you are looking for a Quick Estimate on any of our products, please fill out the short form below so our sales team can help you with pricing.

See Related products

See Related Products

Powder Coating Booths

Upgrade your finishing process with our state-of-the-art powder coating booths.

Convection ovens

We specialize in crafting a wide range of custom power coating ovens, including conveyor belt systems and batch ovens.