Commercial Automotive Paint Booths

Commercial Automotive Paint Booths

Spray-TEch Car Paint Booths

Built For ShopS Like Yours

Automotive Repair & Collision Centers

We build booths that help both large and small collision centers reduce cycle times, meet VOC standards, and maintain a clean finish, all while maximizing available shop space.

Fleet & Heavy Equipment

From buses and semis to agricultural machinery, our oversized booths handle your largest finishing jobs. We offer custom widths, pit designs, and roll-up door systems for smooth, safe workflow — all backed by rugged construction for daily industrial use.

Custom Auto Shops & Restoration

We work with custom shops and restoration specialists across the country to support detailed, high-end paintwork.

Find The Perfect Car Paint Booth

Find Your Airflow

Find Your Product Line

Customize Booth Size

get pricing or connect with the support team.

Sturdy Construction

Constructed with 18 gauge galvanized steel. Includes double layer 14-gauge stiffeners assembled with carriage bolts.

Doors

All personnel doors are placed per code, double skinned with UL listed fire door frames and include large tempered glass windows.

Easy-To-use Control Panels

Our standard control panels are user-friendly and built for straightforward operation and customization. These systems are designed to simply meet the needs of busy automotive shops while ensuring smooth booth functionality.

Fully Compliant

Safety and code compliance is our top priority, guiding the design of every paint booth we offer. Our booths are all OSHA and NFPA approved

Spray-tech Finishing

Professional Automotive Paint Booths

Made In The USA

Manufacturer Backed Warranty

65+ Years Experience

NFPA/Osha Compliant

Built For ShopS Like Yours

Automotive Repair & Collision Centers

We build booths that help both large and small collision centers reduce cycle times, meet VOC standards, and maintain a clean finish, all while maximizing available shop space.

Fleet & Heavy Equipment

From buses and semis to agricultural machinery, our oversized booths handle your largest finishing jobs. We offer custom widths, pit designs, and roll-up door systems for smooth, safe workflow — all backed by rugged construction for daily industrial use.

Custom Auto Shops & Restoration

We work with custom shops and restoration specialists across the country to support detailed, high-end paintwork.

Build The Perfect Car Paint Booth

ALL AIRFLOW TYPES AVAILABLE

CUSTOM BOOTH SIZES

MULTIPLE MODEL TYPES

Accessories & Add Ons

Our Auto Paint Booth models

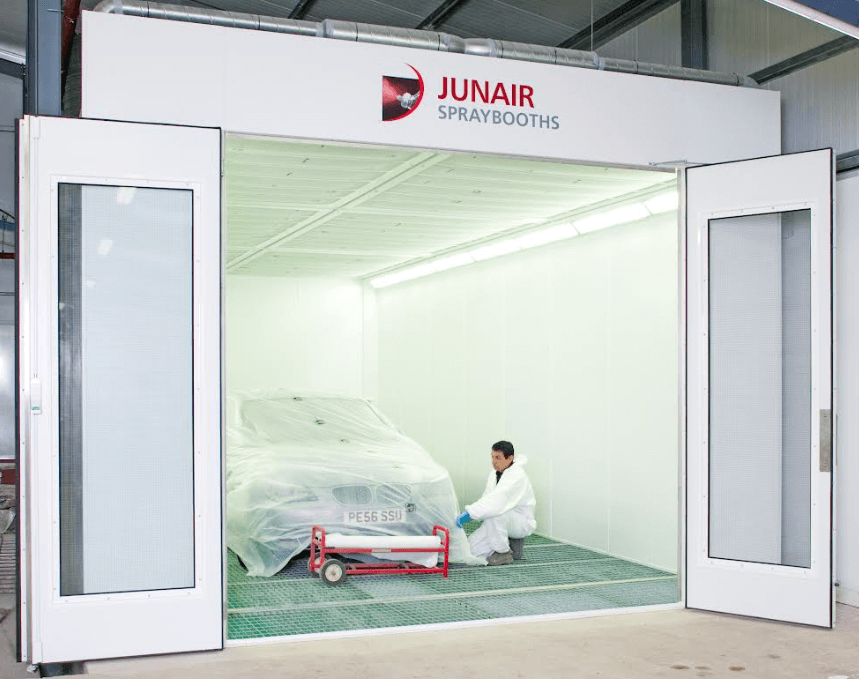

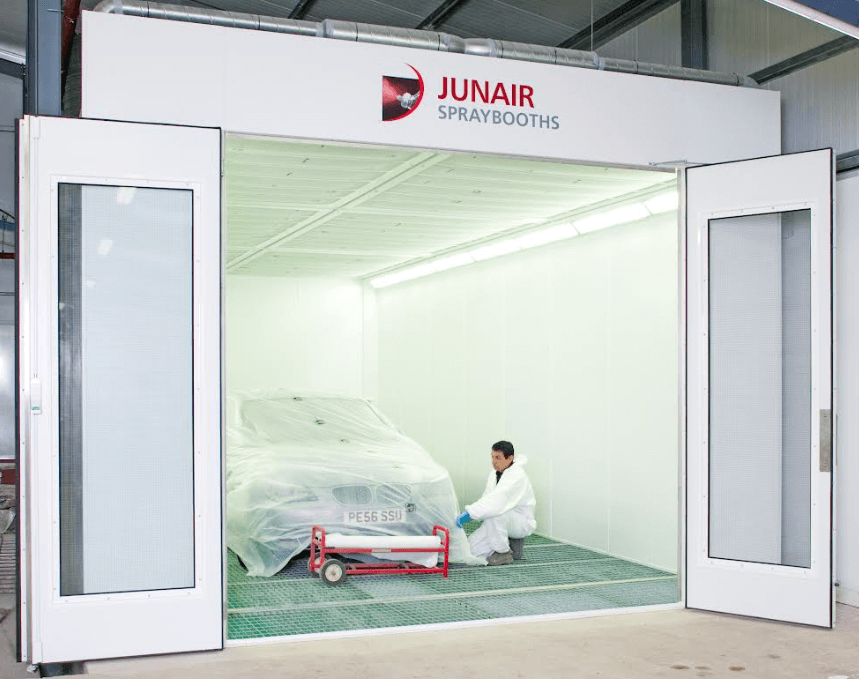

The Junair Series systems are known for their high production capacities. Popular in America, Europe, and around the world. Junair paint booths are incredibly efficient and exceedingly environmentally sound when compared to any other booth on the market.

The premier series paint booths provide an excellent finish among any paint booths in the industry. The advanced control panel and high tech features of this series make the life of the auto body shop owner extremely easy.

The Power Series paint booths utilize highly advanced technology and incorporate air-make-up units above the paint booth to save floor space. Configured to any air flow movement.

Thermaire paint booths are an affordable option. It provides a simple operator interface with all of the air movement, heat, and lighting needed for great paintwork. Configured to any air flow movement.

Airflow Options

Side-draft

Vertical Airflow: Air enters through filters on the side walls and moves horizontally across the work area before exiting through filters on the opposite side, reducing the chances of contaminants settling on wet surfaces.

Enhanced Visibility: This setup often provides better lighting and visibility as the airflow supports a cleaner and clearer working environment, essential for precision tasks.

Semi Down-Draft

Improved Airflow Pattern: Air enters through the ceiling at the front of the booth and moves diagonally towards the rear and downward, enhancing paint quality by minimizing dust and overspray accumulation on the painted surface.

Balance of Cost and Quality: Offers a balance between the cost-effectiveness of cross draft and the superior finish quality of full down-draft systems.

Crossflow

Cost Efficiency: Cross draft booths are typically less expensive to build and install since they require simpler ductwork and fewer fans.

Even Airflow: Air enters through filters at one end of the booth and moves horizontally across the vehicle towards the exhaust at the opposite end, providing even airflow that helps achieve a consistent finish.

Down-draft

Superior Finish Quality: Air enters from the ceiling and moves downward over the object, exiting through the floor. This vertical airflow pattern helps carry contaminants and overspray away from the vehicle, resulting in a cleaner and higher-quality finish.

Reduced Contamination: The downward flow reduces the likelihood of dust or particles settling on the surface during painting, which is crucial.

Find The Perfect Car Paint Booth

get pricing or connect with the support team.

Add-Ons

AUTO PREP STATIONS

Mixing Rooms

Air makeup Units

Paint Booth Lighting

Energy Efficient Paint Booths

The Spray-Tech builds systems that are designed to save energy. At Spray-Tech, energy conservation isn’t just a concept. The Spray-Tech facility itself incorporates many energy saving technologies. We believe saving energy and utility costs has universal application, and these energy cost saving ideas are built into the equipment we provide.

The Spray-Tech builds systems that are meticulously designed to save energy. At Spray-Tech, energy conservation isn’t just a concept but a core principle. The Spray-Tech facility itself is a testament to this commitment, incorporating numerous energy-saving technologies. We believe that saving energy and reducing utility costs have universal benefits, and these energy-saving ideas are seamlessly integrated into the equipment we provide.

Many of the energy-saving features of our systems are utilized by customers to reduce their capital expenses by applying for energy rebates from their local utility suppliers. During this process, Spray-Tech engineers actively collaborate with our customers, providing detailed justification and robust support for energy rebate applications. This partnership ensures that our customers can maximize their savings and achieve their energy efficiency goals effectively.

Purchasing Equipment is Tax Deductible

IRS allows businesses to deduct the full price of qualifying equipment. If you buy (or lease) a piece of qualifying equipment, you can deduct the FULL PURCHASE PRICE from your gross income. Give us a call today to discuss your specific needs.

Contact our sales team for pricing!

Proudly Made In The USA

65+ Years of Experience

Manufacturer Backed Warranty

NFPA/Osha Compliant

Customize Your Paint Booth

Find Your Airflow

Find Your Product Line

Customize Booth Size

Control Panels

Our standard control panels are user-friendly and built for straightforward operation and customization. These systems are designed to simply meet the needs of busy automotive shops while ensuring smooth booth functionality.

Construction

Constructed with 18 gauge galvanized steel. Includes double layer 14-gauge stiffeners assembled with carriage bolts.

Doors

All personnel doors are placed per code, double skinned with UL listed fire door frames and include large tempered glass windows.

Code Compliance

Safety and code compliance is our top priority, guiding the design of every paint booth we offer. Our booths are all OSHA and NFPA approved

Customer Service & Get Estimate Forms

Paint Booth Model Types

The Junair Series systems are known for their high production capacities. Popular in America, Europe, and around the world. Junair paint booths are incredibly efficient and exceedingly environmentally sound when compared to any other booth on the market.

The premier series paint booths provide an excellent finish among any paint booths in the industry. The advanced control panel and high tech features of this series make the life of the auto body shop owner extremely easy.

The Power Series paint booths utilize highly advanced technology and incorporate air-make-up units above the paint booth to save floor space. Configured to any air flow movement.

Thermaire paint booths are an affordable option. It provides a simple operator interface with all of the air movement, heat, and lighting needed for great paintwork. Configured to any air flow movement.

Paint Booth Airflow Types

Side-draft

Vertical Airflow: Air enters through filters on the side walls and moves horizontally across the work area before exiting through filters on the opposite side, reducing the chances of contaminants settling on wet surfaces.

Enhanced Visibility: This setup often provides better lighting and visibility as the airflow supports a cleaner and clearer working environment, essential for precision tasks.

Full Downdraft

Superior Finish Quality: Air enters from the ceiling and moves downward over the object, exiting through the floor. This vertical airflow pattern helps carry contaminants and overspray away from the vehicle, resulting in a cleaner and higher-quality finish.

Reduced Contamination: The downward flow reduces the likelihood of dust or particles settling on the surface during painting, which is crucial for achieving a flawless finish.

Semi DownDraft

Improved Airflow Pattern: Air enters through the ceiling at the front of the booth and moves diagonally towards the rear and downward, enhancing paint quality by minimizing dust and overspray accumulation on the painted surface.

Balance of Cost and Quality: Offers a balance between the cost-effectiveness of cross draft and the superior finish quality of full down-draft systems.

Cross Draft

Cost Efficiency: Cross draft booths are typically less expensive to build and install since they require simpler ductwork and fewer fans.

Even Airflow: Air enters through filters at one end of the booth and moves horizontally across the vehicle towards the exhaust at the opposite end, providing even airflow that helps achieve a consistent finish.

Side-draft

Vertical Airflow: Air enters through filters on the side walls and moves horizontally across the work area before exiting through filters on the opposite side, reducing the chances of contaminants settling on wet surfaces.

Enhanced Visibility: This setup often provides better lighting and visibility as the airflow supports a cleaner and clearer working environment, essential for precision tasks.

Full Downdraft

Superior Finish Quality: Air enters from the ceiling and moves downward over the object, exiting through the floor. This vertical airflow pattern helps carry contaminants and overspray away from the vehicle, resulting in a cleaner and higher-quality finish.

Reduced Contamination: The downward flow reduces the likelihood of dust or particles settling on the surface during painting, which is crucial for achieving a flawless finish.

Semi DownDraft

Improved Airflow Pattern: Air enters through the ceiling at the front of the booth and moves diagonally towards the rear and downward, enhancing paint quality by minimizing dust and overspray accumulation on the painted surface.

Balance of Cost and Quality: Offers a balance between the cost-effectiveness of cross draft and the superior finish quality of full down-draft systems.

Cross Draft

Cost Efficiency: Cross draft booths are typically less expensive to build and install since they require simpler ductwork and fewer fans.

Even Airflow: Air enters through filters at one end of the booth and moves horizontally across the vehicle towards the exhaust at the opposite end, providing even airflow that helps achieve a consistent finish.

Eco Friendly Products

The Spray-Tech builds systems that are designed to save energy. At Spray-Tech, energy conservation isn’t just a concept. The Spray-Tech facility itself incorporates many energy saving technologies. We believe saving energy and utility costs has universal application, and these energy cost saving ideas are built into the equipment we provide.

The Spray-Tech builds systems that are meticulously designed to save energy. At Spray-Tech, energy conservation isn’t just a concept but a core principle. The Spray-Tech facility itself is a testament to this commitment, incorporating numerous energy-saving technologies. We believe that saving energy and reducing utility costs have universal benefits, and these energy-saving ideas are seamlessly integrated into the equipment we provide.

Many of the energy-saving features of our systems are utilized by customers to reduce their capital expenses by applying for energy rebates from their local utility suppliers. During this process, Spray-Tech engineers actively collaborate with our customers, providing detailed justification and robust support for energy rebate applications. This partnership ensures that our customers can maximize their savings and achieve their energy efficiency goals effectively.