Made In The USA

65+ Years of Experience

Manufacturer Backed Warranty

Osha & NFPA Compliant

Precision Engineering

Industrial paint Finishing Systems

From Spray-Tech

Proudly Made In The USA

65+ Years of Experience

Manufacturer Backed Warranty

NFPA/Osha Compliant

Industrial Paint Lines For Any Industry

Industry Leaders

With more than 65 years of expertise, Spray-Tech is a trusted name in high-performance automotive and industrial finishing systems. We design equipment that saves time, energy, and resources—always compliant with OSHA and NFPA standards.

Modular Assemblies

Our systems ship in modular assemblies, pre-wired and pre-plumbed to cut installation time. Wiring looms and pre-engineered connections simplify setup, reducing field labor and getting your finishing line operational faster.

Warranty & Customer Service

Our engineers are on-site for two weeks and available for follow-up for over 18 months to ensure every detail is right. From design through installation and spare parts, we provide responsive support and smart solutions tailored to your finishing needs

Industry Leaders

With more than 65 years of expertise, Spray-Tech is a trusted name in high-performance automotive and industrial finishing systems. We design equipment that saves time, energy, and resources—always compliant with OSHA and NFPA standards.

Modular Assemblies

Our systems ship in modular assemblies, pre-wired and pre-plumbed to cut installation time. Wiring looms and pre-engineered connections simplify setup, reducing field labor and getting your finishing line operational faster.

Warranty & Customer Service

Our engineers are on-site for two weeks and available for follow-up for over 18 months to ensure every detail is right. From design through installation and spare parts, we provide responsive support and smart solutions tailored to your finishing needs

Industry Leaders

With more than 65 years of expertise, Spray-Tech is a trusted name in high-performance automotive and industrial finishing systems. We design equipment that saves time, energy, and resources—always compliant with OSHA and NFPA standards.

Modular Assemblies

Our systems ship in modular assemblies, pre-wired and pre-plumbed to cut installation time. Wiring looms and pre-engineered connections simplify setup, reducing field labor and getting your finishing line operational faster.

Warranty & Customer Service

Our engineers are on-site for two weeks and available for follow-up for over 18 months to ensure every detail is right. From design through installation and spare parts, we provide responsive support and smart solutions tailored to your finishing needs

Powder coating

Our powder coating systems are available in both batch and conveyor designs, delivering durable finishes, high transfer efficiency, and reduced environmental impact for a wide variety of parts and production needs..

Wet spray painting

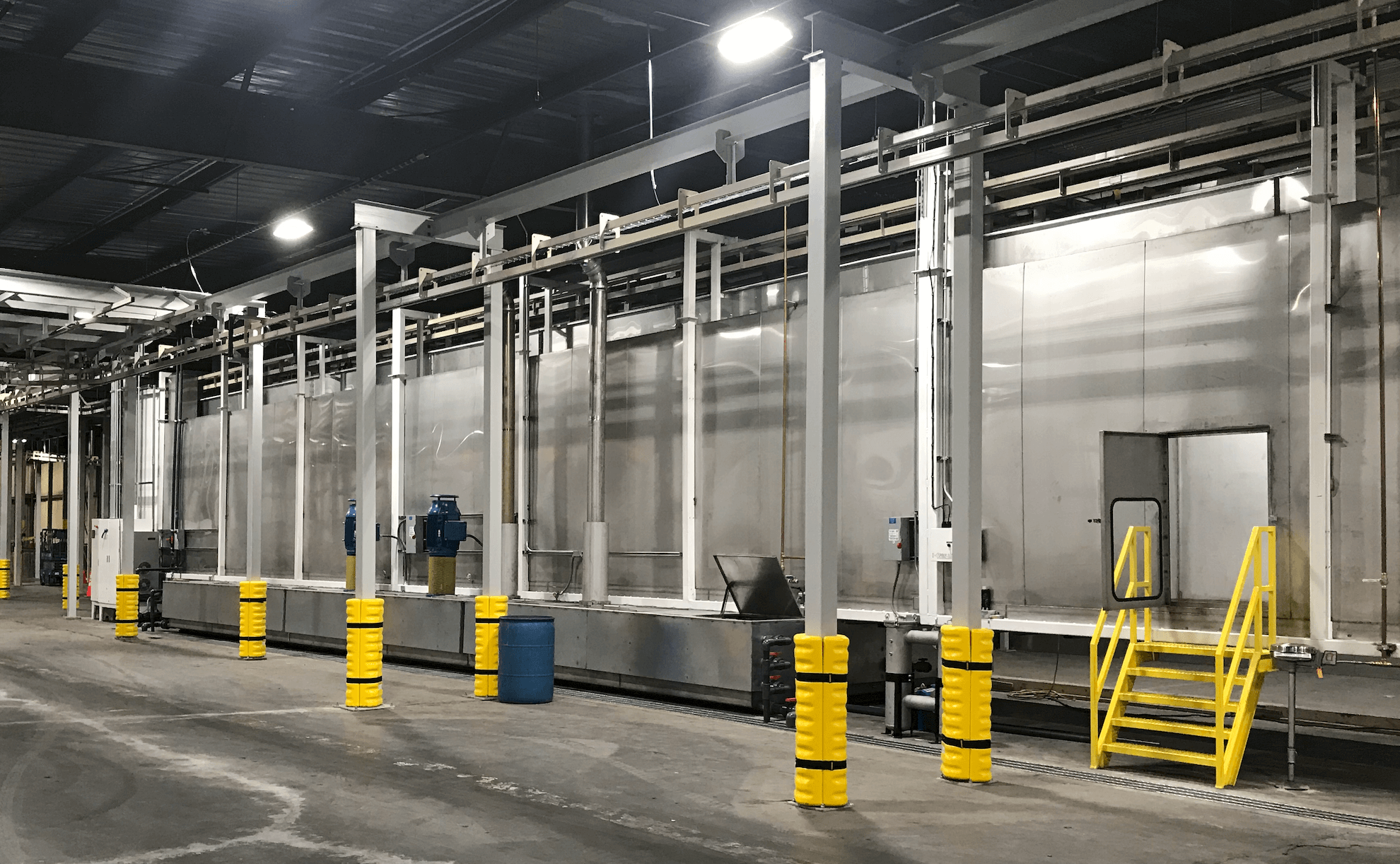

From manual batch booths to fully automated conveyor lines, our wet spray systems provide versatile finishing solutions with exceptional coverage and quality across many industries.

Dip Lines

Whether set up as a standalone batch process or integrated into a continuous production line, our dip coating systems deliver uniform finishes and reliable protection for a broad range of applications.

Electrocoating

Our electrocoating equipment supports both batch immersion tanks and conveyorized systems, applying corrosion-resistant, water-based coatings with consistent coverage on complex geometries.

Paint Line Product Options

Our paint finishing conveyor systems are engineered to move parts efficiently through each stage of the paint and finishing process. Designed for flexibility, they can be configured to fit your specific layout, part size, and production volume. Whether overhead, floor-mounted, or power and free, each system ensures smooth, continuous movement to keep your operation running efficiently.

For lower-volume or specialized operations, our batch finishing systems offer the same high-quality results with greater control and flexibility. Ideal for custom jobs or varied part sizes, these systems allow operators to manually move parts through each stage of the finishing process while still benefiting from Spray-Tech’s proven performance and durability.

Our Pre-Treatment Washers are built in pre-assembled, pre-plumbed modules and thoroughly tested in our shop to reduce installation time and minimize field labor. Tanks are double welded and leak-tested to ensure durability and a smooth setup process. Stainless steel, self-draining headers are standard, preventing the common failures seen with PVC or CPVC.

Pump materials are chosen based on chemical supplier specs, and high-efficiency motors help cut operational costs. All UL-labeled control panels arrive ready for use, avoiding field certification delays.

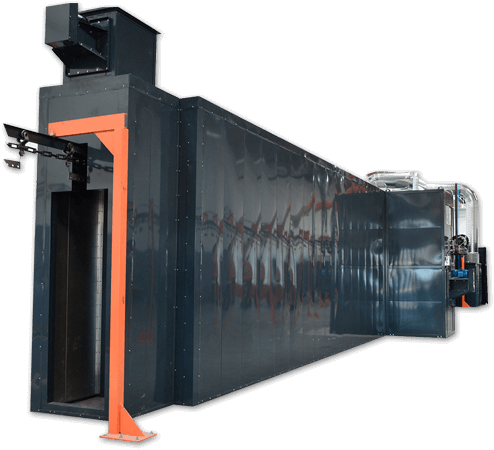

Arriving in pre-assembled modules, our paint curing ovens have both gas or electric burner systems wired to junction boxes, making installation fast and efficient. Designed for durability and consistent performance, they feature automated controls and energy-efficient systems to deliver high-quality finishes while reducing operating costs.

Each oven is built with heavy-duty insulated panels to maintain precise temperatures and minimize heat loss. Flexible configurations allow integration with batch or conveyor finishing lines, giving manufacturers the ability to scale production as needed.

Our Services

Professional Installation

Our project management experience in this highly specialized industry sector is second-to-none.

We Provide Consulting

Your project is in capable hands with authorized Spray Tech / Junair personnel and distributors.

Ongoing Maintenance

We understand it is imperative that your equipment and finishing system operates efficiently and safely at all times.

State of the Art Design

Spray Tech / Junair/Junair can enhance your profit through seasoned facility design expertise and process knowledge.

Repair Services

Our network of authorized distributors ensures that your finishing system operates at peak efficiency 24/7.

World Class Manufacturing

We employ lean manufacturing techniques so we can decrease costs and pass on the savings to you.

Contact us

Code Compliance

OSHA - Occupational Safety and Health Administration

Our commitment to safety aligns with OSHA’s guidelines and regulations, ensuring a secure working environment for all.

NFPA - National Fire Protection Association

Spray-Tech is committed to upholding and advancing the rigorous safety measures advocated by NFPA to ensure a secure and compliant environment for our clients.

ETL - Electrical Testing Labs

We work hard to meet ETL standards in order to ensure our electrical equipment meets rigorous safety and performance criteria.

EPA - Environmental Protection Agency

Our environmental responsibility is reflected in our compliance with EPA regulations, contributing to a cleaner and sustainable future.